Barcodes are a cornerstone of modern inventory and data management systems, but their effectiveness hinges on accurate data capture. This is where barcode validation comes into play.

Barcode validation ensures that the barcodes used in your operations are accurate, readable, and reliable.

In this article, we will learn the concept of barcode validation, explore its importance, and discuss the differences between barcode validation and verification.

Can You Check if a Barcode is Valid?

Yes, you can check if a barcode is valid through several methods:

1. Manual Inspection: Visually inspect the barcode to ensure that it appears complete and free of printing defects. This can catch obvious errors but is not sufficient for ensuring full validity.

2. Software Validation Tools: Utilize specialized software to check the barcode's data integrity and format. These tools can decode the barcode and verify that it meets the required standards.

3. Scanner Testing: Test the barcode using multiple barcode scanners to ensure it can be read consistently. This step helps verify the barcode's practical usability in real-world scenarios.

By integrating these methods into your validation process, you can ensure that your barcodes are reliable and effective.

What is Barcode Validation?

Barcode validation is the process of ensuring that a barcode is correctly formatted and contains the appropriate data before it is used or printed.

This step is crucial in maintaining the integrity of data in supply chain operations, retail, healthcare, and many other industries. Validation checks that the barcode conforms to specific standards and can be accurately decoded by barcode scanners.

How Do You Validate a Barcode?

Validating a barcode involves several steps:

1. Data Integrity Check: Ensuring that the data encoded within the barcode is correct and meets the expected format.

For example, a UPC barcode should have a specific number of digits. This involves verifying the numerical or alphanumerical data to prevent mismatches and errors.

2. Format Verification: Confirming that the barcode adheres to the standards set for the specific barcode type. Different barcode types (such as UPC, QR codes, and Code 128) have unique formatting rules. Ensuring compliance with these standards is crucial for universal readability.

3. Readability Test: Using a barcode scanner to ensure that the barcode can be easily read. This helps identify any printing issues or design flaws that could hinder scanning. It is advisable to test the barcode with multiple scanners to account for variations in scanning technology.

4. Error Detection: Checking for any potential errors in the barcode data that could lead to scanning problems or data inaccuracies. This might include verifying checksum digits or other embedded error-checking features within the barcode.

What is the Difference Between Barcode Validation and Verification?

Understanding the difference between barcode validation and verification is critical for effective barcode management:

● Barcode Validation: This process ensures that the barcode data is correct and properly formatted before it is used. It focuses on the accuracy and integrity of the barcode's content, ensuring that the encoded information adheres to the necessary standards.

● Barcode Verification: This is the process of assessing the quality of a printed barcode.

Verification examines the barcode's physical characteristics, such as contrast, spacing, and edge definition, to ensure it meets industry standards for print quality. Verification is typically performed after the barcode is printed and involves detailed analysis of the barcode's print quality.

While validation ensures the data accuracy before a barcode is used, verification ensures the barcode's print quality and readability post-production. Both processes are essential but serve different purposes in the lifecycle of a barcode.

Best Practices for Barcode Validation

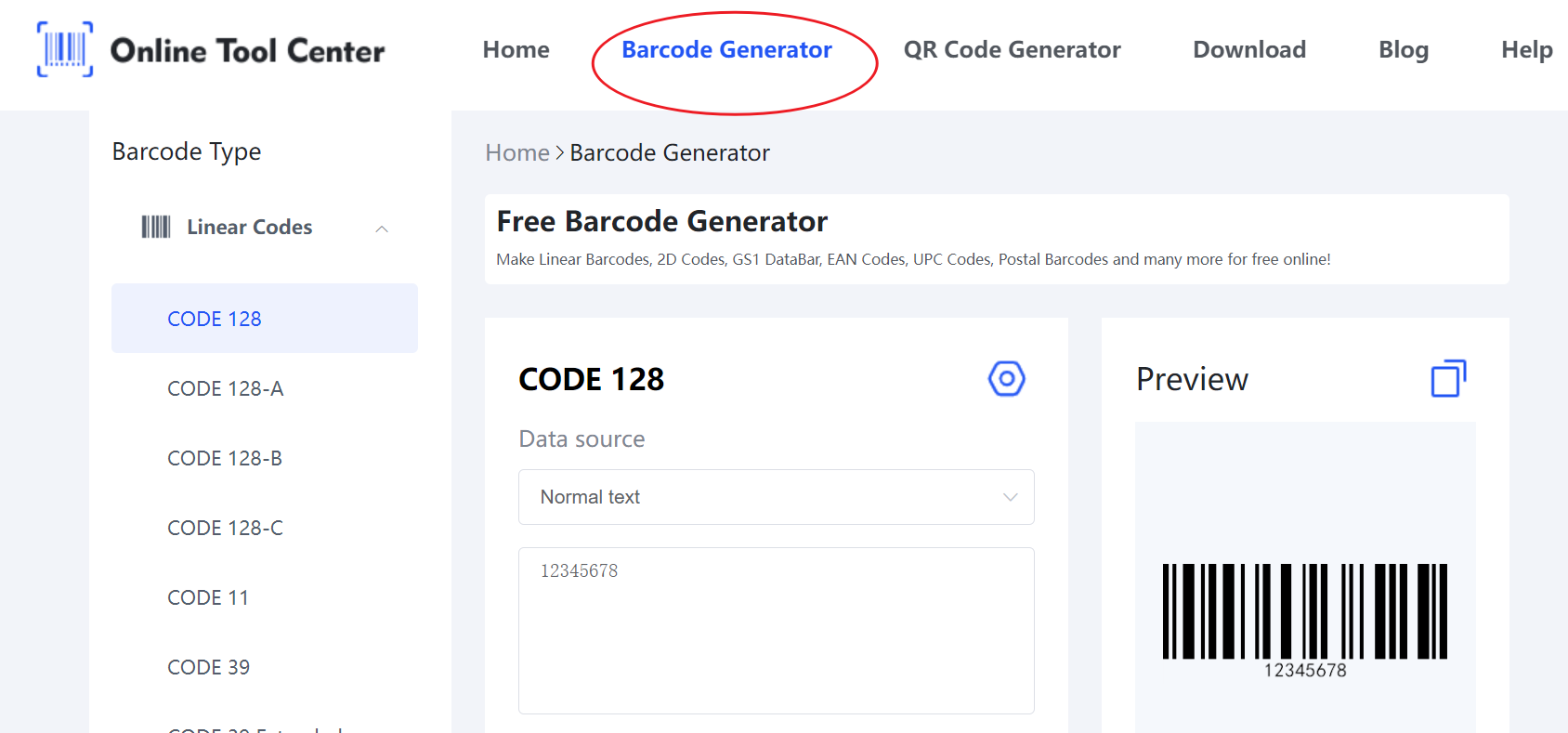

1. Use Reliable Software: Utilize trusted barcode generation and validation software to minimize the risk of errors. Tools like our barcode generato can help ensure your barcodes are correctly formatted and validated.

2. Regular Scanning: Periodically test your barcodes with different scanners to ensure consistent readability across various devices. This practice helps in identifying any compatibility issues that might arise with different scanner models.

3. Training: Educate your team on the importance of barcode validation and train them on the proper methods for validating barcodes. Proper training ensures that all personnel are aware of the standards and procedures necessary for effective barcode management.

4. Compliance Checks: Stay updated with industry standards and regulations related to barcode use and ensure your validation process aligns with these requirements. Compliance with standards like GS1 ensures that your barcodes will be universally readable.

5. Quality Control: Implement a robust quality control process to catch any issues in barcode generation before they can affect your operations. Regular audits and checks can help maintain the quality and reliability of your barcodes.

In general, incorporating barcode validation into your barcode management process is essential for maintaining data accuracy and operational efficiency.

By understanding and implementing the principles of barcode validation, you can ensure that your barcodes are both accurate and reliable, which is critical for effective inventory and data management.

For those looking to generate and validate barcodes, tools like the free barcode generator can provide an excellent resource. Remember, accurate barcodes are the backbone of efficient and error-free data management.