In the dynamic world of retail and logistics, the accuracy and readability of barcodes are important. Barcode verification is a crucial process that ensures barcodes meet quality standards, thereby enhancing operational efficiency and reducing errors.

This article explores the importance of barcode verification, the technology behind it, and how businesses can integrate it into their workflows.

What is Barcode Verification?

Barcode verification is the process of analyzing barcodes to ensure they comply with industry standards and can be reliably scanned.

This differs from barcode scanning, which reads the information encoded in a barcode.

Barcode verification involves a detailed examination of the barcode's quality and performance using specialized equipment known as barcode verifiers.

What are the Standards for Barcode Verification?

The standards for barcode verification are primarily set by international organizations such as the International Organization for Standardization (ISO).

Key standards include ISO/IEC 15416 for linear (1D) barcodes and ISO/IEC 15415 for two-dimensional (2D) barcodes.

These standards specify the criteria for evaluating barcode quality, including symbol contrast, modulation, defects, and decodability, ensuring that barcodes are accurately and reliably read across different scanning environments.

How Barcode Verification Works?

Barcode verifiers assess barcodes against specific criteria set by international standards.

The key aspects evaluated include:

● Symbol Contrast: This measures the difference in reflectance between the barcode's dark bars and light spaces. High contrast is essential for readability.

● Modulation: This evaluates the uniformity of the barcode's bars and spaces. Inconsistent modulation can lead to scanning errors.

● Defects: This identifies any imperfections in the barcode, such as spots or voids, that could affect readability.

● Decodability: This checks if the barcode can be accurately interpreted by scanners.

A barcode verification scanner captures an image of the barcode and analyzes it against these criteria. The scanner then assigns a grade, typically ranging from A (excellent) to F (failing), indicating the barcode's quality.

Why is Barcode Verification Important?

1. Error Reduction: Poor quality barcodes can lead to scanning errors, resulting in incorrect data entry, shipment errors, and inventory discrepancies. Verification minimizes these risks.

2. Compliance: Many industries, including healthcare and logistics, have strict barcode quality standards. Barcode verification ensures compliance with these standards, avoiding potential fines and operational disruptions.

3. Efficiency: Reliable barcodes streamline processes such as checkout, stocktaking, and order fulfillment, reducing time and labor costs.

How to Choose the Right Barcode Verifier?

Selecting the appropriate barcode verifier is critical for ensuring accurate verification. Consider the following factors:

1. Type of Barcode: Ensure the verifier supports the types of barcodes used in your operations, whether linear (1D) or 2D barcodes.

2. Industry Standards: Verify that the device complies with relevant industry standards to ensure compatibility and reliability.

3. Ease of Use: Look for user-friendly interfaces and comprehensive documentation to simplify the verification process.

4. Reporting Capabilities: Advanced verifiers provide detailed reports and analytics, aiding in quality control and continuous improvement.

How to Do Barcode Verification?

Barcode verification involves several steps to ensure that barcodes meet quality standards and can be reliably scanned:

1. Select the Appropriate Barcode Verifier:

Choose a barcode verifier that is compatible with the type of barcodes you use (e.g., linear (1D) or two-dimensional (2D)). Ensure the verifier complies with relevant industry standards.

2. Prepare the Barcode:

Ensure the barcode is printed on a clean, flat surface without any distortions or damage.

Avoid placing the barcode on curved or textured surfaces, as this can affect its readability and verification accuracy.

3. Capture the Barcode Image:

Use the verifier's high-resolution camera or scanning head to capture an image of the barcode.

Make sure the barcode is properly aligned and within the verifier's field of view.

4. Analyze the Barcode:

The verifier will analyze the barcode's key quality parameters, including symbol contrast, modulation, defects, and decodability.

These parameters are measured against predefined standards to assess the barcode's overall quality.

5. Review the Verification Report:

The verifier generates a detailed report that assigns a grade to the barcode, typically ranging from A (high quality) to F (failing).

The report highlights any issues and provides insights into specific areas that need improvement.

6. Take Corrective Actions:

Based on the verification report, make any necessary adjustments to the barcode printing process to address identified issues.

Regularly verify barcodes during production to ensure consistent quality and compliance with standards.

By following these steps, businesses can ensure their barcodes are of high quality and meet industry standards, thereby reducing errors and improving operational efficiency.

Case Study: Improving Logistics Efficiency with Barcode Verification

A leading logistics company faced frequent shipping errors and inventory discrepancies due to unreadable barcodes. By integrating barcode verification into their quality control process, they achieved a significant reduction in errors.

They used advanced barcode verifiers to conduct routine checks and ensured all barcodes met the required standards. As a result, they saw a 30% increase in scanning accuracy and a 20% reduction in operational costs within six months.

To sum up, barcode verification is essential for maintaining accuracy, efficiency, and compliance in retail and logistics operations.

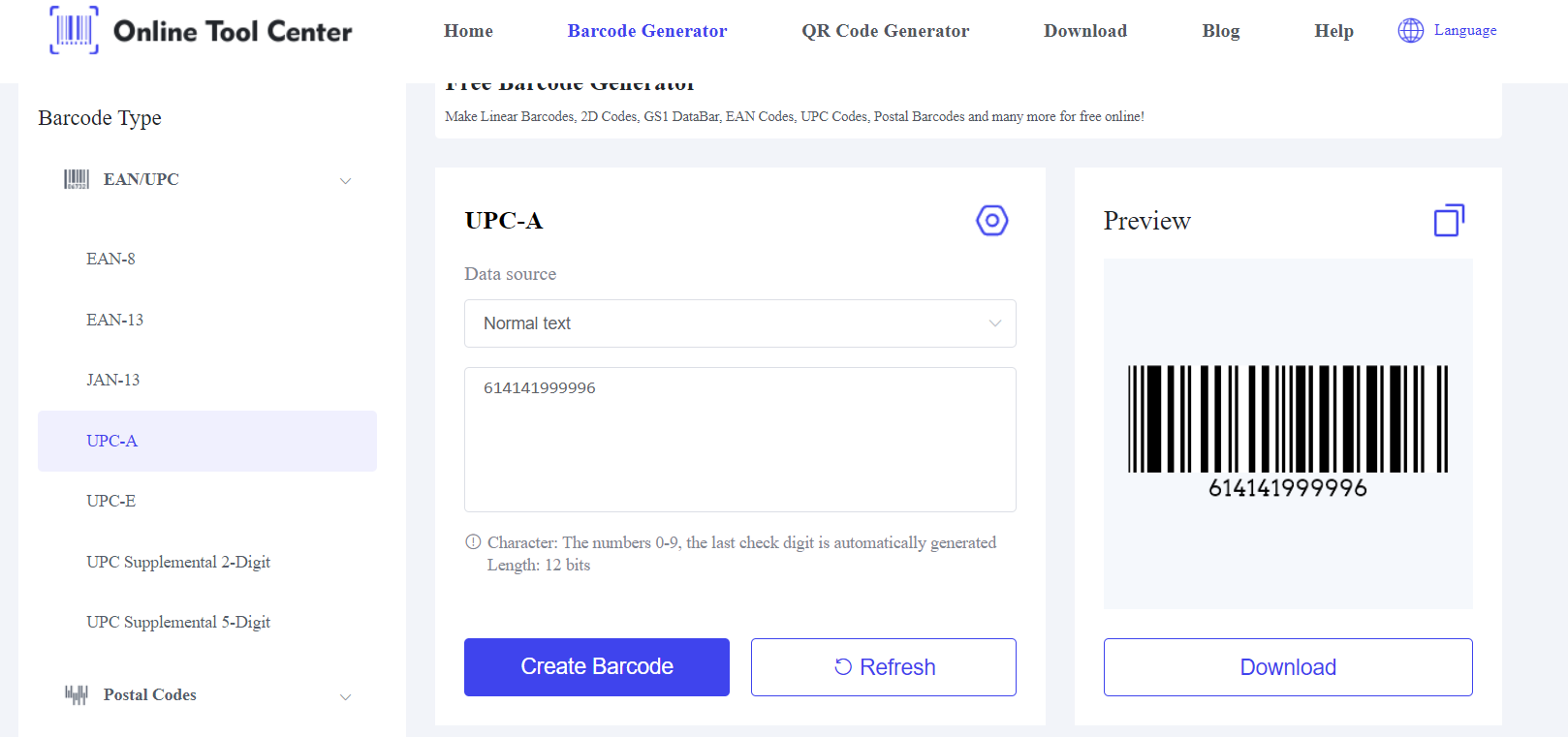

The use of barcode verifiers and barcode verification scanners is critical in this process. Additionally, pairing verification with a free barcode generator ensures that the barcodes you produce are compliant.