Fragrance barcodes play a crucial role in inventory management, sales tracking, and ensuring product authenticity. This article will explore the significance of fragrance barcodes and provide a comprehensive guide on generating and checking them.

What is a Fragrance Barcode?

A fragrance barcode is a unique identifier assigned to a fragrance product, allowing it to be tracked through various stages of the supply chain. These barcodes facilitate efficient inventory management, accurate sales tracking, and help maintain product authenticity.

Typically, fragrance barcodes follow the standard formats such as UPC (Universal Product Code) or EAN (European Article Number), ensuring global compatibility and ease of use.

Types of Barcodes Used in Fragrances

● UPC (Universal Product Code)

The UPC is one of the most common barcodes used in retail, including the fragrance industry. It consists of a series of black and white bars that represent numerical data. Each UPC is unique to a specific product, making it easy to identify and track items.

● QR Codes

How QR Codes are Used in the Fragrance Industry?

QR codes are two-dimensional barcodes that can store a large amount of data, including website URLs, product details, and promotional information.

In the fragrance industry, QR codes can be used for marketing purposes, allowing customers to scan the code with their smartphones to access information about the fragrance, promotional offers, or to verify authenticity.

Interactive and Marketing Uses of QR Codes

QR codes offer interactive experiences for consumers. For instance, scanning a QR code on a fragrance bottle might take a customer to a video showcasing the fragrance's creation process or to customer reviews.

● EAN (European Article Number)

The EAN is similar to the UPC but is primarily used outside of North America. It includes additional digits that expand its data capacity, making it suitable for international markets.

EAN barcodes help streamline global supply chains by providing a standard method of identifying products across different countries.

Importance of Fragrance Barcodes

1. Inventory Management

● Streamlining Inventory Processes: Fragrance barcodes streamline inventory processes by enabling quick and accurate scanning of products. This efficiency reduces the time spent on manual data entry and minimizes the risk of human error.

● Reducing Human Error: Manual inventory management is prone to mistakes, such as incorrect product counts or misplaced items. Barcodes automate this process, significantly reducing the chances of errors and ensuring accurate inventory data.

2. Sales and Marketing

● Tracking Sales Data: Barcodes provide valuable sales data, allowing businesses to monitor product performance in real-time. This data helps in making informed decisions about stock levels, pricing strategies, and promotional activities.

● Enhancing Marketing Strategies: By analyzing sales data obtained from barcodes, companies can identify trends and preferences, allowing them to tailor marketing strategies to meet consumer demand more effectively.

3. Product Authenticity

● Ensuring the Authenticity of Products: Counterfeit fragrances are a significant concern in the industry. Barcodes help verify the authenticity of products by providing a unique identifier that can be traced back to the manufacturer.

● Combating Counterfeit Fragrances: Implementing barcodes on fragrance products makes it easier to track and identify counterfeit items, protecting both the brand and the consumer.

How to Generate Fragrance Barcodes?

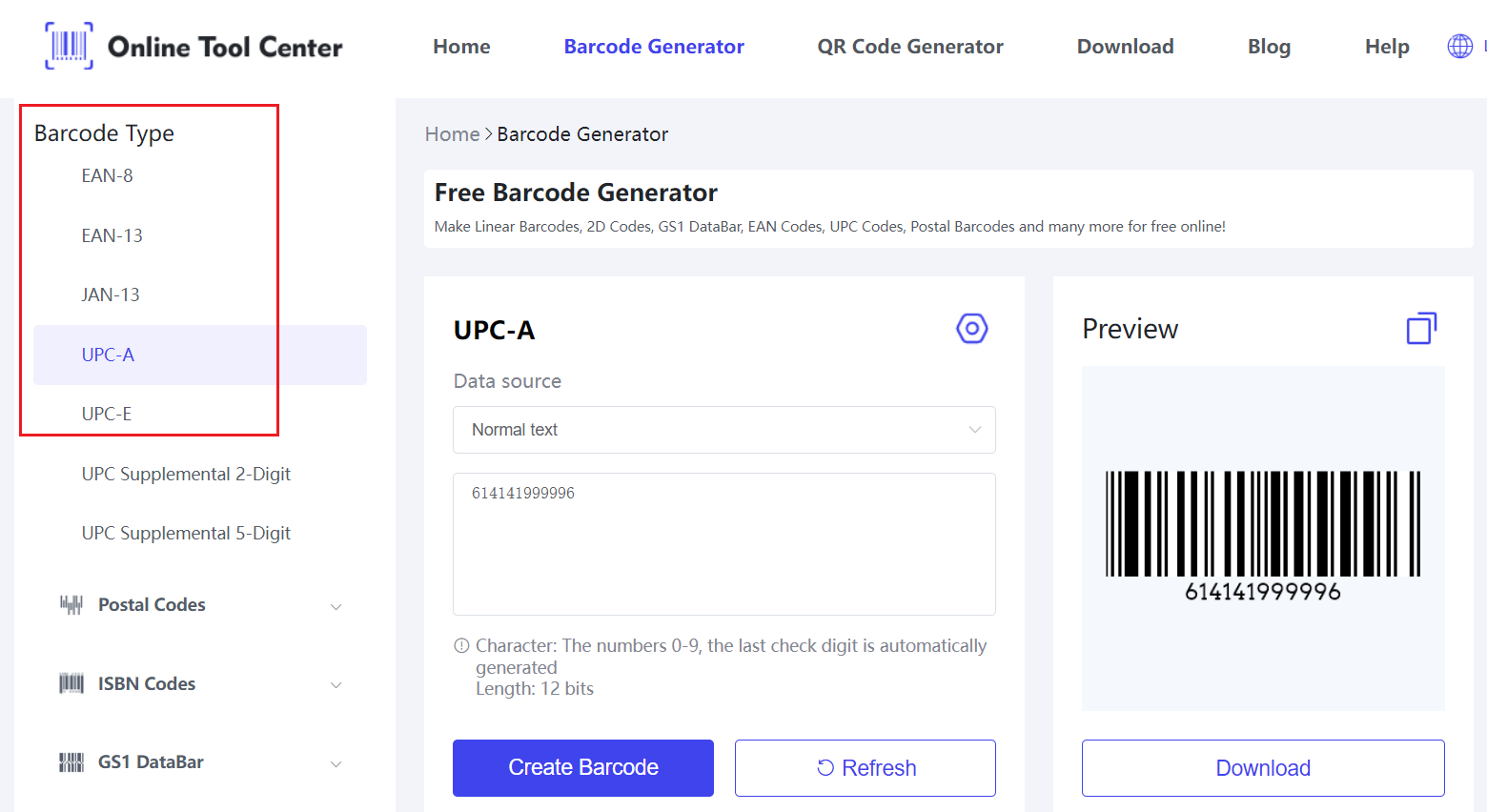

1. Selecting a Barcode Generator: Choose a online barcode generator.

2. Select a Barcode Type: Decide whether you need a UPC, QR code, or EAN based on your market and application.

3. Register for a Barcode Number: Obtain a unique barcode number from a legitimate organization like GS1.

4. Inputting Product Information: Enter the necessary product details.

5. Generating the Barcode: Generate a barcode for each product. Ensure the barcode is clear and scannable.

6. Print and Test: Print the barcode on your packaging and test it with a barcode scanner to ensure it works correctly.

Best Practices for Barcode Placement

Proper placement of barcodes is critical for ensuring they can be easily scanned. Here are some guidelines:

● Visibility: Place the barcode in a visible area on the packaging, avoiding edges and folds.

● Contrast: Ensure there is a high contrast between the barcode and the background for easy scanning.

● Size: Maintain the appropriate size for the barcode to ensure it is readable by standard scanners.

● Avoid Distortion: Do not distort the barcode by stretching or shrinking it, as this can affect its readability.

Tools for Fragrance Barcode Check

Overview of Popular Barcode Checking Tools: Various tools are available for barcode checking, each offering unique features. Popular options include handheld scanners and mobile apps.

Features to Look For in a Barcode Checker: When selecting a barcode checker, consider features such as compatibility with different barcode formats, ease of use, and integration with inventory management systems.

Case Studies and Examples

Large Fragrance Retailer: A major fragrance retailer implemented barcodes to streamline its inventory processes. The result was a significant reduction in human error and improved stock management.

Small Boutique Fragrance Brand: A small boutique brand used barcodes to enhance its marketing strategies. By analyzing sales data, the brand was able to tailor its product offerings to meet customer preferences, resulting in increased sales.

In summary, fragrance barcodes are essential for efficient inventory management, accurate sales tracking, and ensuring product authenticity.

We encourage you to explore the barcode generator for generating barcodes to streamline your operations and ensure the authenticity of your products.

FAQs

1. What is the barcode on perfume?

The barcode on perfume is a unique identifier that allows the product to be tracked through the supply chain, from manufacturing to retail.

2. Are there any regulations for fragrance barcodes?

Yes, fragrance barcodes must comply with industry standards such as UPC or EAN to ensure global compatibility and accuracy.