When managing inventory and tracking products, businesses often rely on either barcodes or serial numbers. Each identification system plays a crucial role in modern product management, but they function quite differently.

Understanding the strengths and limitations of both systems can help you choose the best approach for your business.

This article will explore the differences between barcodes and serial numbers, how they complement each other, and why using a barcode serial number can be highly beneficial.

What is a Serial Number?

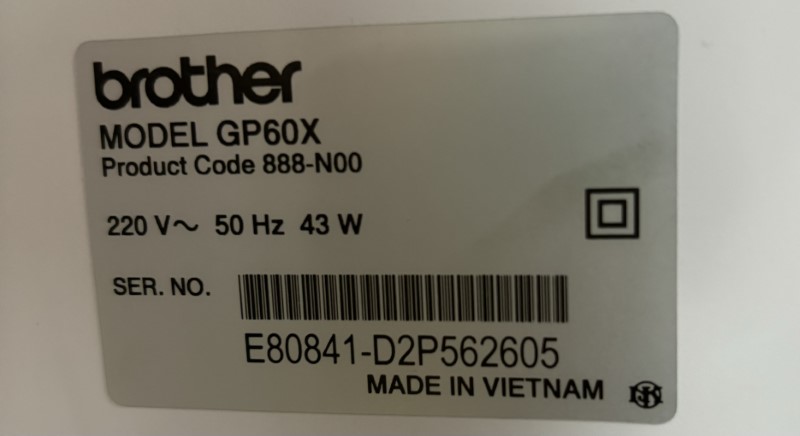

A serial number is a unique identifier assigned to a single item. Each product manufactured, sold, or distributed receives its serial number, ensuring that no two items share the same identifier. These numbers are typically alphanumeric and can vary in length, depending on the manufacturer's specifications.

For example, in electronics manufacturing, a serial number can help track devices during production, monitor warranty periods, and verify product authenticity.

If a customer reports an issue, the serial number helps manufacturers pinpoint when and where the product was made, enabling more effective support and recall efforts.

In industries such as automotive, medical devices, and luxury goods, serial numbers are essential for compliance and warranty claims. They ensure each product can be individually tracked throughout its lifecycle.

What is a Barcode?

A barcode is a machine-readable representation of data, typically consisting of a series of black and white bars or, in the case of QR codes, squares. A barcode encodes information, such as product identification numbers, making it easier for machines to read and process data.

In retail, barcodes usually encode information like product type, manufacturer, and pricing. Common types of barcodes include the Universal Product Code (UPC) and European Article Number (EAN). These barcodes are standard in grocery stores, warehouses, and logistics companies because they allow for quick and accurate scanning.

Benefits of Using a Barcode Serial Number System

1. Faster Data Entry:

Manually entering a serial number can be time-consuming and prone to mistakes. A barcode serial number allows the same information to be scanned in seconds, improving efficiency in processes like inventory management and order fulfillment.

2. Enhanced Accuracy:

By reducing the need for manual data entry, a barcode serial number minimizes the risk of human error. This is especially valuable in industries where accurate product tracking is crucial, such as medical devices or automotive parts.

3. Improved Traceability:

Combining a serial number with a barcode offers better traceability throughout the supply chain. It provides real-time data about the product's location, condition, and history, which can be invaluable in case of a recall or product defect.

Barcode vs. Serial Number: Key Differences

Though both barcodes and serial numbers are used to identify products, they serve different purposes:

Feature | Barcode | Serial Number |

Purpose | Identifies product category or type | Uniquely identifies individual items |

Readability | Scanned quickly with a barcode reader | Must be manually read and entered |

Automation | Easily integrated into automated systems | Requires manual data entry unless combined with a barcode |

Scope | Applies to groups of products (e.g., same model) | Applies to a single, unique product |

Format | Visual bars or QR codes, machine-readable | Alphanumeric characters, human-readable |

Size | Compact and standardized | Can be long and variable in length |

Efficiency | Faster and more accurate data entry | Prone to human error when manually input |

Use Case | Ideal for retail, inventory, and logistics | Ideal for warranty tracking and recalls |

Combination | Can encode serial numbers for enhanced tracking | Unique to each product; not inherently scannable |

1. Identification Scope:

● A serial number is unique to an individual item. It identifies that specific item and is used to track its history, including warranty and support.

● A barcode, by contrast, usually identifies a category of products rather than an individual item. For example, all units of a specific product model share the same barcode, but they will each have a unique serial number.

2. Readability and Automation:

● A serial number is meant to be read and processed manually, though it can also be incorporated into a barcode for easier scanning. Manually entering a serial number is prone to human error and takes more time.

● A barcode can be scanned instantly, making data entry and processing faster and more efficient. This automation is invaluable in high-volume settings, like warehouses and retail environments, where speed and accuracy are crucial.

3. Size and Formatting:

● Serial numbers vary in length and format, often alphanumeric. While serial numbers are essential for specific tracking, their length and complexity can make them difficult to print on smaller items.

● Barcodes, on the other hand, can store the same or even more information in a smaller, standardized format, making them easier to apply to small products or labels.

4. Use in Supply Chains:

● In supply chain management, using barcodes simplifies the movement of products from manufacturing to the consumer. It's easy to scan items in bulk, which streamlines processes such as inventory management and shipping.

● Serial numbers become more critical when detailed tracking of individual units is necessary, such as in cases of recalls or high-value items where knowing the exact history of each product is vital.

Combining Barcodes and Serial Numbers

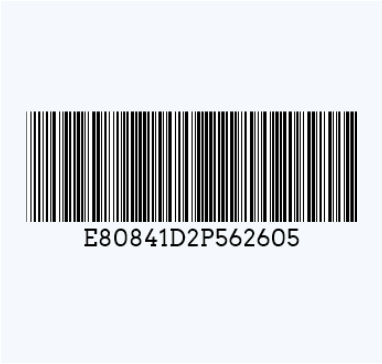

In many industries, combining barcodes with serial numbers offers the best of both worlds. A barcode serial number encodes the product's serial number into a machine-readable format, allowing businesses to track individual items with the speed and accuracy of barcode scanning.

This combination is especially useful in industries like:

1. Manufacturing:

Manufacturers often assign a serial number to each product for internal tracking, but by embedding that serial number in a barcode, they can automate much of the production process. Scanning the barcode serial number helps monitor quality control, product assembly, and shipping in real time.

2. Pharmaceuticals:

In the pharmaceutical industry, accuracy and traceability are paramount. Transparency serial number barcodes are used to track individual medications, ensuring that drugs are authentic and haven't been tampered with. These serial numbers on barcodes also assist in recalls, allowing companies to trace exactly which batches of medication need to be removed from shelves.

3. Electronics:

For electronics, serial numbers are key to warranty tracking and technical support. By integrating the serial number into a barcode, companies can scan devices during repair or return processes, improving efficiency and reducing the likelihood of errors.

In summary, both barcodes and serial numbers serve crucial functions in product identification, but they are even more powerful when used together. A barcode serial number combines the unique identification of a serial number with the automation and speed of a barcode, making it ideal for businesses looking to streamline operations and improve accuracy.

For businesses seeking an easy way to generate barcodes, the barcode generator offers a simple, efficient solution. Take advantage of this tool to improve your product tracking and inventory management systems today.