Barcode truncation is a critical issue in the world of product identification and inventory management.

As businesses rely heavily on barcodes for efficient operations, understanding and preventing truncation is crucial.

This article discovers the intricacies of barcode truncation, its causes, impacts, and solutions, providing valuable insights for businesses and individuals alike.

What is Barcode Truncation?

Barcode truncation occurs when a barcode is reduced in height or width to an extent that compromises its readability. This reduction can make it difficult or impossible for barcode scanners to accurately read the encoded information.

In today's fast-paced commercial and logistical environments, where barcodes play a pivotal role in tracking and identifying products, truncation can lead to significant inefficiencies and errors.

To comprehend barcode truncation, it's essential to first understand how barcodes work. Barcodes come in two main types: 1D (linear) and 2D barcodes.

Linear barcodes, such as UPC and Code 128, consist of parallel lines and spaces of varying widths, while 2D barcodes, like QR codes, use patterns of squares, dots, or other shapes to encode information.

The structure of a barcode includes:

1. Quiet zones: Blank areas before and after the barcode

2. Start and stop characters: Indicating the beginning and end of the code

3. Data characters: The main body of encoded information

4. Check digit: For error detection

Root Causes of Barcode Truncation

1. Design-Related Issues:

● Insufficient quiet zones, impeding scanner initialization

● Improper barcode size relative to the scanning environment

● Suboptimal placement on packaging, particularly on curved surfaces

2. Printing-Related Problems:

● Low-resolution printing resulting in unclear or fuzzy barcodes

● Misalignment during the printing process, affecting barcode dimensions

● Improper color contrasts, such as using red ink or low-contrast color combinations

3. Environmental and Handling Factors:

● Exposure to harsh environmental conditions (moisture, heat, or UV light) causing degradation

● Physical damage during transportation, handling, or storage

Impact on Scanning Accuracy and Business Operations

Barcode truncation can significantly impair scanning accuracy, leading to various operational issues:

● Complete scan failures, requiring manual entry of product information

● Misreading of information, resulting in inventory discrepancies or pricing errors

● Multiple scan attempts, slowing down operations and reducing efficiency

Best Practices to Prevent Barcode Truncation

1. Design Guidelines:

● Ensure adequate quiet zones around barcodes (typically 10 times the width of the narrowest bar)

● Choose the correct barcode size and symbology based on the specific application and scanning environment

● Consider the curvature of the product when placing barcodes, using "ladder" orientation for highly curved surfaces

2. Printing Best Practices:

● Utilize high-resolution printers (minimum 300 dpi for most applications)

● Maintain proper color contrast (ideally black on white, with a minimum reflectance difference of 70%)

● Regularly calibrate and maintain printing equipment to ensure consistent output

3. Quality Assurance:

● Implement a rigorous verification process post-printing

● Use ISO/IEC compliant barcode verifiers to check for truncation barcode issues and overall print quality

● Conduct regular sample testing of scanned barcodes in real-world conditions

Solutions for Existing Barcode Truncation Problems

If you're facing barcode truncation issues with existing products, consider these expert solutions:

1. Re-designing Barcodes:

● Adjust barcode size and orientation to fit small packages while maintaining readability

● Switch to more compact barcode formats like EAN-8 or UPC-E for limited space applications

● Consider composite barcodes that combine 1D and 2D elements for enhanced data capacity in limited space

2. Enhancing Printing Processes:

● Upgrade to higher resolution printers with advanced color management capabilities

● Implement direct thermal or thermal transfer printing for improved durability in harsh environments

● Use pre-printed labels with high-quality substrates for better accuracy in mass production

3. Technological Solutions:

● Deploy advanced image-based scanners with improved error correction algorithms

● Implement redundancy in barcode information through supplementary 2D barcodes

● Utilize machine learning-enhanced scanning software for improved read rates of suboptimal barcodes

Industry Applications and Case Studies of Truncation Barcode

1. Retail

A major electronics retailer discovered that barcode truncation on their product labels was causing frequent scanning errors at checkout, particularly for small accessories.

By redesigning their labeling system to use composite barcodes (1D for UPC and 2D for additional product data) and implementing stricter quality control measures, they reduced scanning errors by 92%, significantly improving customer satisfaction and operational efficiency.

2. Logistics and Supply Chain

A global e-commerce fulfillment center found that truncation barcode issues were causing misrouting of packages, leading to delays and increased shipping costs.

By implementing a comprehensive barcode quality assurance program, including inline verification systems and staff training on proper handling techniques, they reduced misrouting incidents by 78% within three months and saw a 12% increase in overall operational efficiency.

FAQs about Truncation Barcode

1. How much can you truncate a barcode?

The acceptable level of truncation varies by barcode type and scanning environment. Generally, linear barcodes should not be truncated below 80% of their standard height to maintain readability.

However, for optimal performance, full-height barcodes are recommended whenever possible.

2. What are the most effective strategies to prevent barcode truncation in product packaging?

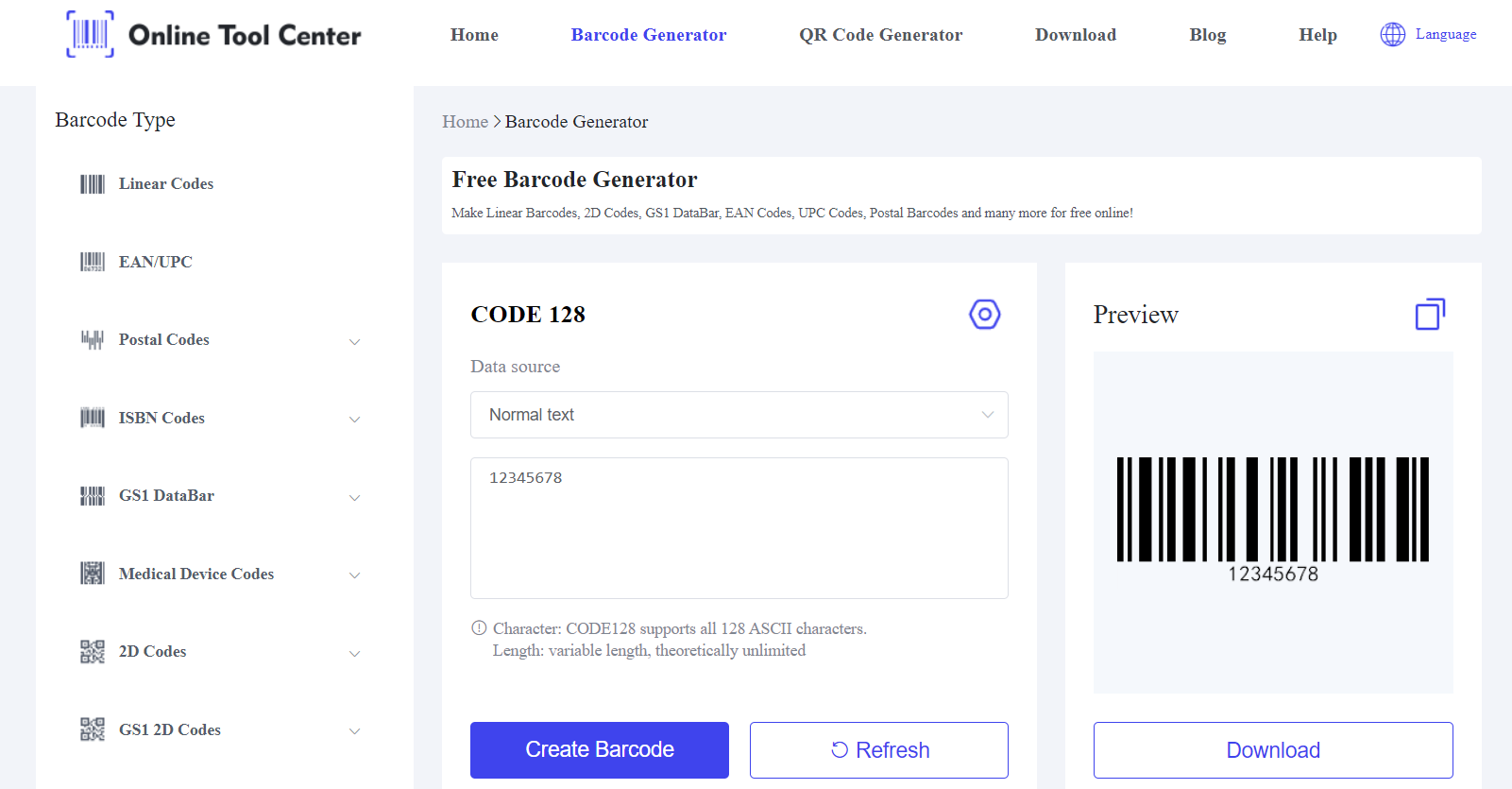

Key strategies include ensuring proper design with adequate quiet zones, using high-quality printing processes, implementing regular quality checks, and utilizing an online barcode generator that adheres to industry standards.

All in all, barcode truncation remains a significant challenge across various industries, potentially leading to operational inefficiencies, errors, and financial losses.

To ensure the highest quality barcodes and minimize the risk of truncation barcode problems, it's essential to use professional, standards-compliant barcode generation tools.

Our free barcode generator offers accurate barcode generation services, helping businesses create high-quality barcodes that meet industry standards and reduce the likelihood of truncation issues.