Barcodes are the backbone of modern data management and inventory systems, playing a pivotal role in industries ranging from retail to healthcare. As technology and industry need to evolve, so too do the designs and colors of barcodes.

The yellow barcode is one such innovation, offering unique advantages in specific applications. This article explores the concept of yellow barcodes, exploring their characteristics, benefits, and best practices for implementation.

What Are Yellow Barcodes?

A yellow barcode refers to a barcode that utilizes yellow as either the color of the bars or the background.

This variation can be particularly effective in environments where traditional black-and-white barcodes may not provide optimal visibility or where branding and design considerations are paramount.

The core function of the barcode remains unchanged, but the color adjustment can lead to different visual and functional outcomes.

Visual Characteristics of Yellow Barcode

The primary difference between a yellow barcode and a standard barcode lies in the visual contrast. Typically, barcodes are designed with black bars on a white background to maximize contrast and ensure readability.

However, when yellow is introduced, either in the bars or the background, it can create a unique visual effect that enhances or diminishes readability based on the surrounding environment.

For example, a yellow background with black bars can stand out more effectively in low-light environments, improving scan accuracy and speed.

Types of Barcodes Compatible with Yellow Coloring

Various barcode formats, both 1D and 2D, can incorporate yellow coloring, each serving different industry needs.

1. 1D Barcodes

● UPC and EAN Codes: These are the most commonly used barcodes in retail. Incorporating yellow in these codes, especially as a background color, can improve visibility on brightly colored or patterned packaging, ensuring more reliable scanning at checkout counters.

● Code 39 and Code 128: These barcodes are frequently used in logistics and manufacturing, where large volumes of goods need to be tracked efficiently.

A yellow barcode can help distinguish critical items quickly, especially in environments where lighting is poor or where quick visual identification is necessary.

2. 2D Barcodes

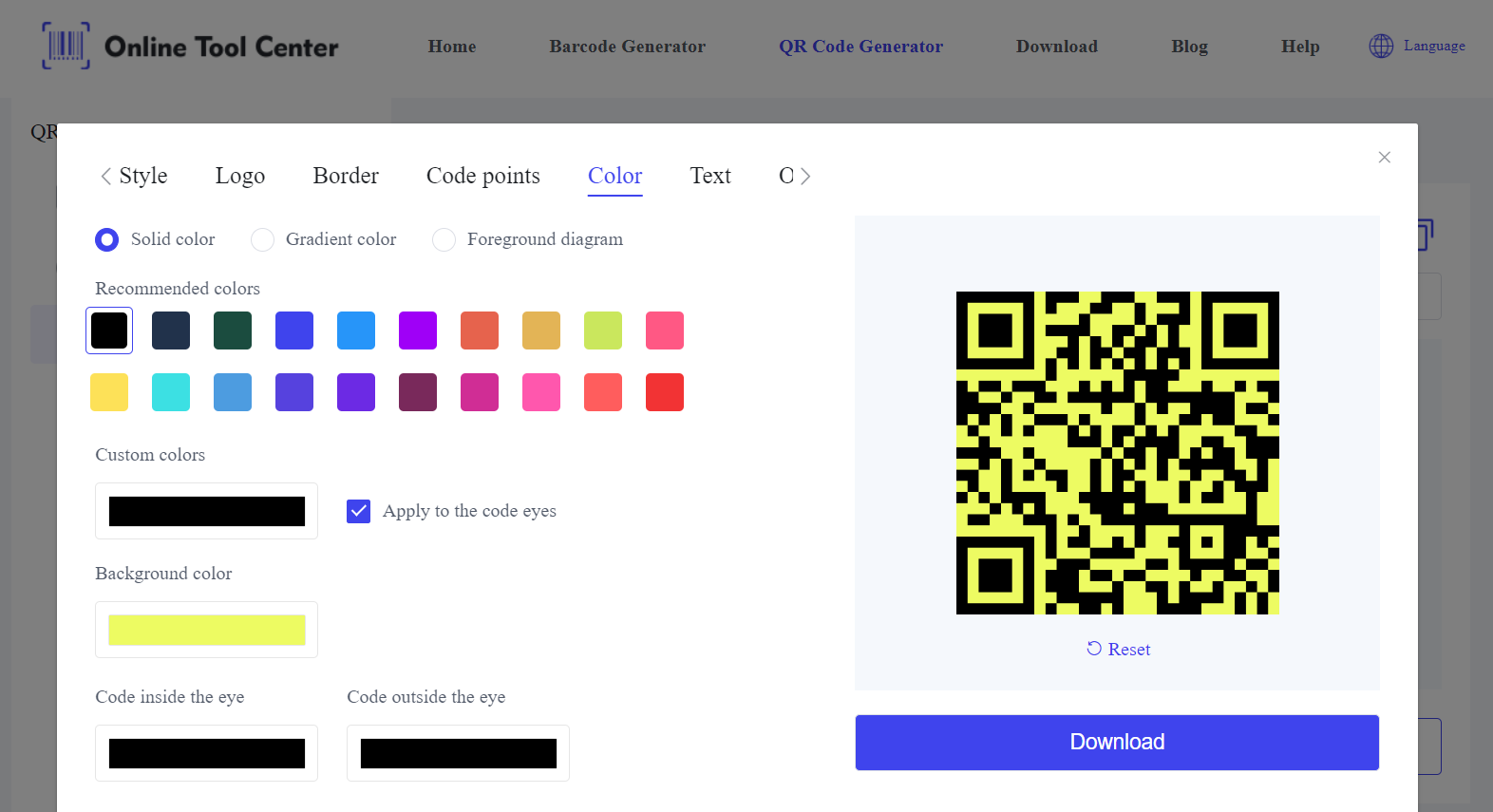

● QR Codes: QR codes are widely used for a range of purposes, from marketing to payment systems.

A yellow barcode in the form of a QR code can be an excellent way to incorporate brand colors into packaging, making the code a seamless part of the overall design without compromising functionality.

● Data Matrix: Used extensively in the electronics and pharmaceutical industries, Data Matrix codes are compact and require precise scanning.

A yellow Data Matrix barcode can improve visibility on small components or packaging, aiding in quick and accurate scanning.

Advantages of Using Yellow Barcodes

1. Enhanced Visibility

One of the most significant advantages of a yellow barcode is its enhanced visibility under specific lighting conditions.

In environments such as warehouses, where lighting can be inconsistent, a yellow barcode can be easier to spot and scan, reducing errors and speeding up processes.

2. Branding and Aesthetics

Yellow barcodes offer an opportunity to integrate functional elements like barcodes into a brand's visual identity.

In product packaging, where every detail counts, using yellow barcodes can help maintain the aesthetic integrity of the design while ensuring that the barcode remains functional.

3. Special Use Cases

Yellow barcodes can be particularly useful in reducing scanning errors in challenging environments.

For example, in healthcare, where accurate data entry is critical, yellow barcodes on medication labels can provide better contrast in bright or reflective settings, reducing the likelihood of errors.

Industry Applications of Yellow Barcode

The adaptability of yellow barcodes makes them valuable across various industries, each with its unique requirements.

1. Logistics and Warehousing

Logistics and warehousing operations often take place in environments with varying lighting conditions. Yellow barcodes can be easier to scan in low-light areas, improving efficiency and reducing the potential for errors in inventory management.

2. Electronics

In electronics manufacturing, where components are often small and densely packed, the enhanced visibility of yellow Data Matrix barcodes can improve traceability and quality control, ensuring that every part is accurately tracked throughout the production process.

How to Create Yellow Barcodes?

Creating a yellow barcode involves selecting a barcode generator that allows customization of barcode colors.

Start by choosing the type of barcode you need, such as UPC, Code 39, or QR code. Input the necessary data, then look for options to customize the appearance.

Set the bar color to black or dark to ensure readability, and change the background to yellow.

This contrast is crucial for the barcode to be easily scannable. Once customized, generate the barcode and test it with a barcode scanner to confirm it reads correctly. You can then download and print the barcode on your desired material.

Best Practices for Implementing Yellow Barcodes

1. Color Contrast

To ensure that a yellow barcode is easily readable, it's essential to maintain a high contrast between the barcode and its background.

For example, using black bars on a yellow background is generally effective, as it provides sufficient contrast to ensure that the barcode is scannable in a variety of lighting conditions.

2. Material Selection

Choosing the right material for printing yellow barcodes is crucial to ensure durability and readability over time.

Materials that are resistant to fading or discoloration are ideal, particularly in environments where the barcode might be exposed to harsh conditions.

3. Scanner Compatibility

While most modern scanners are capable of reading colored barcodes, it's important to ensure that they are properly calibrated to handle the specific contrast and color combinations of yellow barcodes.

Regular maintenance and calibration can help avoid potential issues and ensure that yellow barcodes are read accurately.

FAQs

1. Can any barcode be colored yellow?

Yes, virtually any barcode can be colored yellow, provided that there is sufficient contrast between the barcode and its background to maintain readability.

2. Are yellow barcodes compatible with all scanners?

Most modern scanners can read yellow barcodes, but some may require calibration to optimize performance, especially if the contrast is lower than that of traditional black-and-white barcodes.

3. Does barcode color matter?

Yes, barcode color can significantly impact readability. Ensuring high contrast between the barcode and its background is essential for maintaining accurate scanning.

In summary, yellow barcodes offer distinct advantages in terms of visibility, branding, and operational efficiency across a variety of industries.

Whether used in retail, healthcare, logistics, or electronics, yellow barcodes can enhance the readability and functionality of standard barcodes.

For businesses looking to implement yellow barcodes, utilizing an online free barcode generator is essential to ensure that the barcodes meet the necessary standards for readability and performance.