What are UCC Barcodes?

UCC barcodes were first introduced as UCC-128, designed to encode detailed information about products. With the merger of the Uniform Code Council and EAN International, these barcodes are now part of the GS1 system, referred to as GS1-128. This evolution has expanded their use and standardization globally.

UCC barcodes play a critical role in supply chain management. They provide a standardized method to encode detailed product information, facilitating seamless tracking and tracing throughout the supply chain.

This article aims to offer a comprehensive understanding of UCC barcodes. We will explore their structure, uses, benefits, and the process of creating them with a barcode generator.

Basic Structure

A UCC barcode consists of several components:

● Leading quiet zone: A clear area before the barcode starts, ensuring readability.

● Start character: Indicates the beginning of the barcode.

● Symbol characters: Encodes the actual data.

● Check digit: Ensures the barcode is correctly composed.

● Stop character: Indicates the end of the barcode.

● Trailing quiet zone: A clear area after the barcode ends, ensuring readability.

Comparison with Other Barcodes

Unlike standard Code 128 barcodes, UCC barcodes (or GS1-128) include Application Identifiers (AIs) that specify the type of data encoded. This feature makes them more versatile for supply chain applications, as they can encode a wider variety of information compared to other barcode types.

Benefits of UCC Barcodes

1. Enhanced Traceability

UCC barcodes significantly improve the ability to track products from the manufacturer to the retailer. This traceability is crucial for maintaining the integrity of the supply chain and quickly addressing any issues that arise.

2. Increased Efficiency

Automation of receiving processes is a major benefit of UCC barcodes. By reducing the need for manual data entry, these barcodes help decrease paper usage and minimize errors, leading to more efficient operations.

3. Improved Customer Satisfaction

Better inventory management, enabled by UCC barcodes, leads to fewer stockouts and overstock situations.

This ensures that products are available when customers need them, enhancing overall satisfaction.

Components of a UCC Barcode

1. Global Trade Item Number (GTIN)

A GTIN is a unique identifier for products, ensuring that each item can be accurately identified and tracked throughout the supply chain. This identification is crucial for maintaining product integrity and traceability.

2. Batch/Lot Numbers

These numbers are crucial for tracking production batches, which is important for quality control and traceability.

For example, a food manufacturer uses batch numbers to trace the origins of ingredients in case of a quality issue or recall.

3. Serial Numbers

Serial numbers identify individual items, providing a granular level of detail that is useful for inventory management and tracking.

A technology company, for instance, uses serial numbers to track individual devices through production, distribution, and after-sales service.

4. Expiration Dates

Ensuring product freshness compliance with regulations, and expiration dates are critical data points included in UCC barcodes.

A pharmaceutical company, for example, uses expiration dates to manage inventory and ensure that medications are dispensed before they expire.

5. Additional Application Identifiers (AIs)

AIs can encode other critical data points such as production date, due date, and packaging date, providing a comprehensive view of product information.

For instance, a cosmetics company uses AIs to include information about production and packaging dates, ensuring product quality and compliance with regulatory standards.

Uses of UCC Barcodes

1. In Supply Chain Management

UCC barcodes are extensively used in supply chain management for tracking and tracing products.

They are commonly found on pallet shipments and individual cartons, providing detailed information about the contents and facilitating efficient logistics operations.

For example, a global electronics manufacturer uses UCC barcodes to track components from suppliers to assembly lines, ensuring timely deliveries and reducing inventory costs.

2. In Retail

While not typically used at the point of sale due to their information density, UCC barcodes enhance inventory visibility and efficiency in retail environments. They help manage stock levels and streamline the receiving process.

For instance, a large retail chain uses UCC barcodes to monitor inventory levels in real-time, reducing the risk of stockouts and overstock situations.

3. In Regulatory Compliance

UCC barcodes ensure product traceability, which is crucial for recalls and compliance with industry standards.

They help businesses meet regulatory requirements by providing accurate and accessible product information.

A pharmaceutical company, for example, uses UCC barcodes to track medication batches, ensuring compliance with health regulations and facilitating swift recalls if needed.

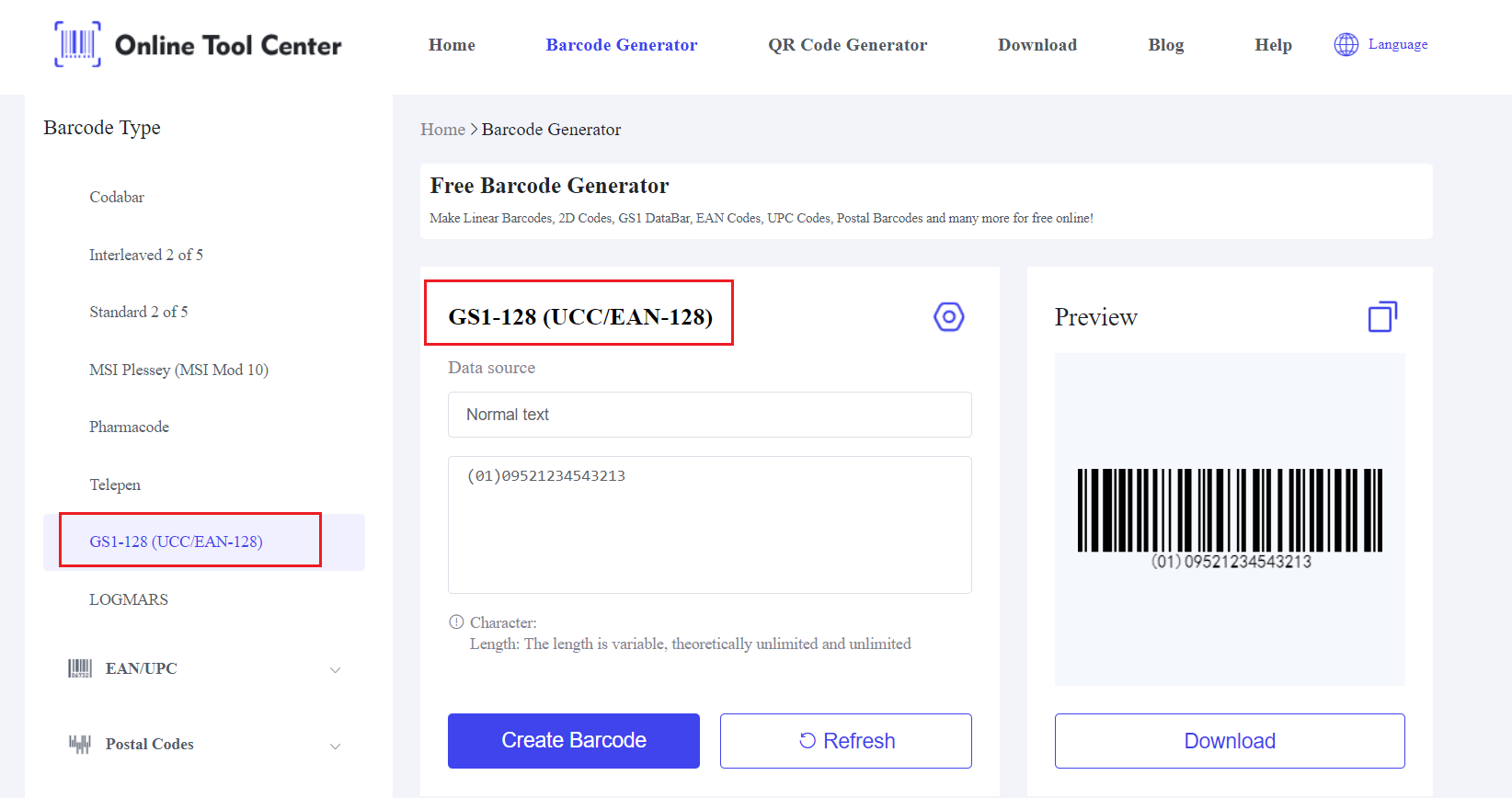

How to Create a UCC Barcode?

To create a UCC barcode, specifically a GS1-128 barcode, start by obtaining a GS1 Company Prefix, which serves as a unique identifier for your business.

Next, assign a unique product identifier, such as a Global Trade Item Number (GTIN), and gather any additional data you wish to include, like batch numbers or expiration dates.

Use an online barcode generator to input this information and generate the barcode.

Once the data is encoded into the GS1-128 format, you can print the barcode using either an online service or professional label printing software, ensuring it meets all size and quality standards for readability and compliance with GS1 guidelines.

Challenges in Implementing UCC Barcodes

1. Retailer-Specific Requirements

Different retailers may have varying requirements for barcodes, which can pose a challenge.

Ensuring your barcodes meet these requirements is essential for smooth operations.

For example, a supplier might need to adjust its barcoding practices to meet the specific needs of major retailers like Walmart or Amazon.

2. Maintaining Compliance

Continuous compliance with GS1 standards is necessary to avoid issues in the supply chain. Staying updated with any changes in standards is crucial.

A compliance officer in a manufacturing firm, for instance, might regularly review GS1 updates to ensure ongoing adherence.

In short, UCC barcodes are a vital component of modern supply chains, offering enhanced traceability, increased efficiency, and improved customer satisfaction.

Start using a barcode generator today to streamline your processes and ensure compliance with industry standards.