Barcodes are a crucial component in the world of retail, manufacturing, and logistics.

A product barcode label serves as the backbone of efficient product management, enabling businesses to streamline operations, enhance accuracy, and improve the customer experience.

In this detailed guide, we'll explore what a product barcode label is, why it's essential, and how you can create and implement one effectively.

What is the Barcode For a Product Label?

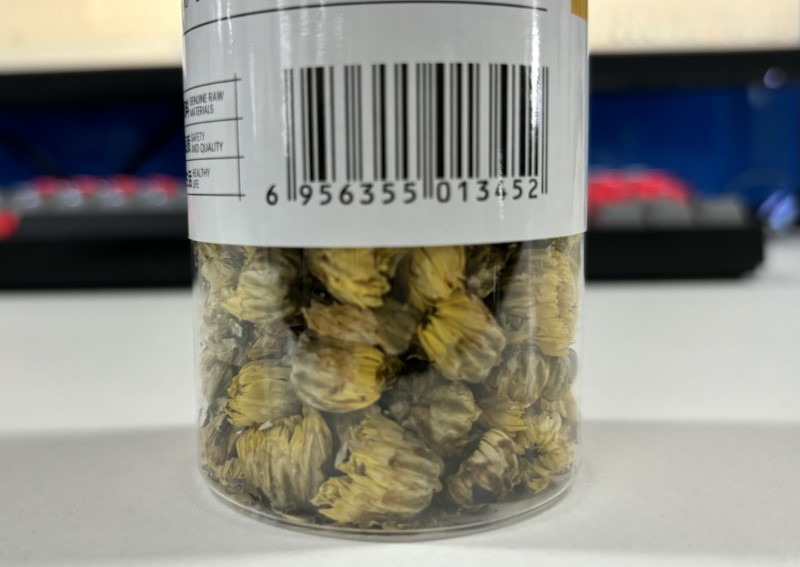

A product barcode label is a label that contains a barcode, a machine-readable representation of data. This barcode encodes specific information about the product, such as its unique identification number (e.g., UPC, EAN), price, and sometimes additional details like batch numbers or expiration dates.

When scanned, the barcode enables quick retrieval of this information, facilitating various business processes like inventory management and sales tracking.

There are different types of barcodes, but the most commonly used in product labeling are:

● UPC: Predominantly used in North America.

● EAN: Widely used internationally.

● QR Codes: Often used for marketing purposes, linking to websites or promotional content.

What Should a Product Barcode Label Include?

The information encoded in a product barcode label can vary depending on the industry and specific product needs. However, it generally includes:

● Product ID: A unique identifier that distinguishes the product from others.

● Price: The selling price of the product.

● Batch or Lot Number: Used for tracking purposes, especially in manufacturing and pharmaceuticals.

● Expiration Date: Critical for perishable goods.

Why is a Product Barcode Label Essential?

The product barcode label is more than just a tag on your product, it's a vital tool for managing and optimizing your business operations. Here's why it's so important:

1. Efficient Inventory Management

Barcodes enable businesses to track inventory. Every time a product is scanned, whether it's being stocked, shipped, or sold, the inventory data is automatically updated. This reduces the likelihood of stockouts or overstock situations, ensuring that inventory levels are always accurate.

2. Streamlined Checkout Processes

When a product barcode label is scanned at the point of sale, it instantly pulls up the product's information, including its price. This speeds up the checkout process, reduces the chances of pricing errors, and enhances the overall customer experience.

3. Improved Accuracy and Reduced Human Error

Manual data entry is prone to errors, which can lead to incorrect pricing, inventory discrepancies, and other costly mistakes. Barcodes eliminate these risks by automating data capture, ensuring accuracy across all business operations.

4. Enhanced Traceability and Security

Barcodes improve product traceability throughout the supply chain.

For industries like pharmaceuticals and food, where safety and compliance are paramount, barcodes can track products from production to sale, reducing the risk of theft and ensuring accountability at every stage.

How to Create a Product Barcode Label?

Creating a product barcode label involves several key steps:

1. Choose the Right Barcode Type

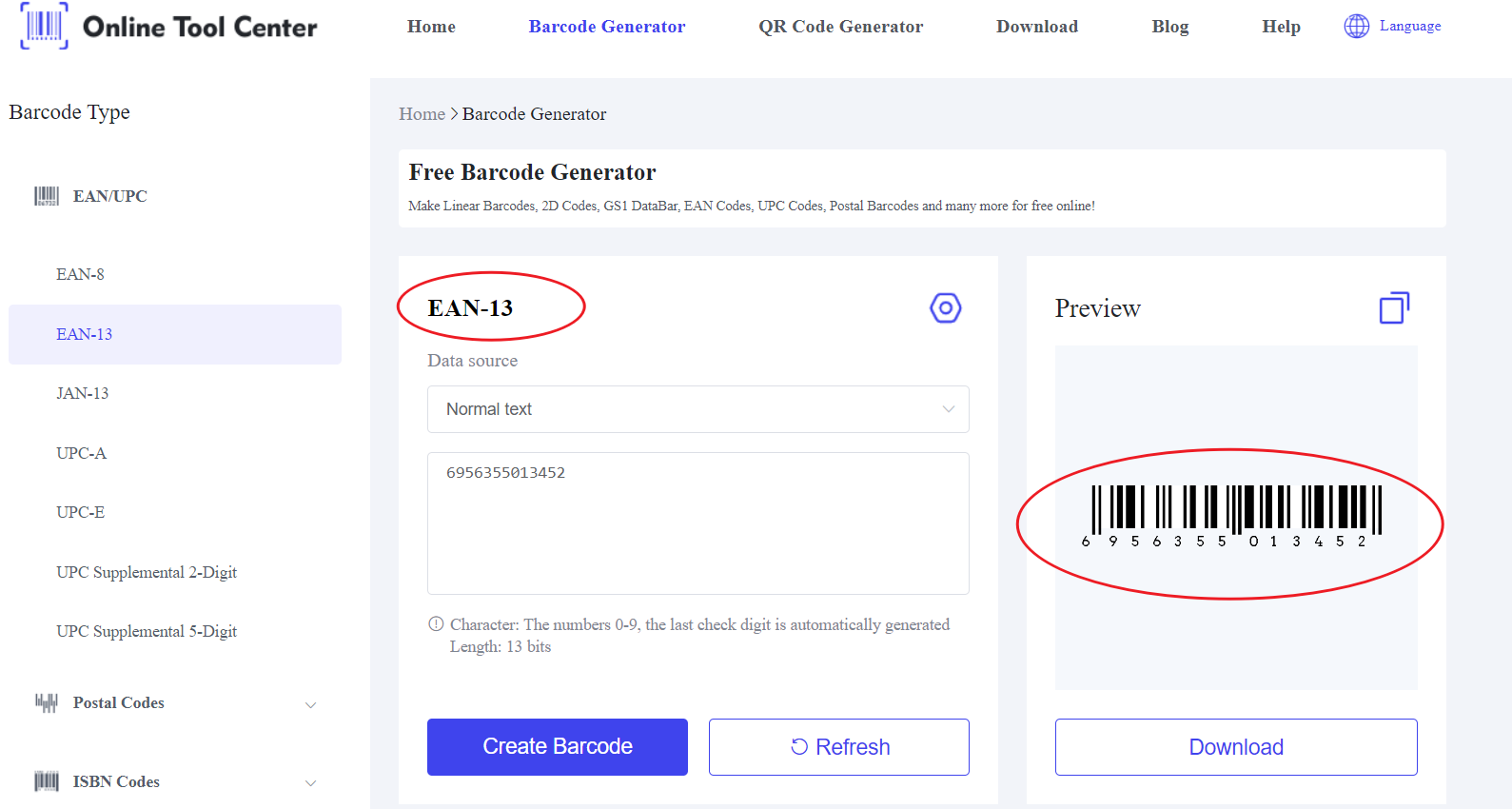

Selecting the appropriate barcode type is crucial. For retail products, UPC or EAN codes are commonly used.

If your product will be sold internationally, an EAN might be more suitable. If you need to encode more information or use the barcode for promotional purposes, a QR code could be ideal.

2. Register Your Barcode

If you're using a UPC or EAN code, you'll need to register it with GS1, the global standards organization for barcodes. GS1 provides unique identification numbers that ensure your product's barcode is recognized worldwide.

3. Use a Barcode Generator

Once you have your barcode number, you can use an online barcode generator to create the barcode. Simply enter the necessary information (like the product ID) into the generator, select the barcode type, and generate the barcode image.

4. Design and Print the Label

Design the label to include the barcode and any additional information required, such as the product name or price. Make sure the barcode is of high quality and printed using a label printer on durable labels that can withstand handling and environmental conditions.

5. Test the Barcode

Before mass-producing the labels, test the barcode to ensure it scans correctly. It's important to verify that the barcode can be read by different types of barcode scanners, under various conditions.

Best Practices for Product Barcode Labels

To maximize the effectiveness of your product barcode label, follow these best practices:

1. Ensure Durability: Use high-quality materials for your labels, especially if the products will be exposed to harsh conditions. Smudged or damaged barcodes can lead to scanning errors.

2. Optimal Placement: Place the barcode in a location that is easy to scan but protected from damage. Common placements include the bottom or back of the product packaging.

3. Regular Updates: If the product information changes (such as the price or batch number), update the barcode accordingly. Ensure that the barcode on the label always reflects the most current data.

In closing, a well-designed product barcode label is an essential component of modern business operations. It enables accurate inventory management, speeds up checkout processes, and improves customer satisfaction.

By following best practices and using a barcode generator, you can create effective and durable barcodes that meet your business needs.

Whether you're a small business owner or managing a large inventory, investing in a robust barcode labeling system will pay off in improved efficiency and reduced errors. Ensure your products are always accurately labeled and easy to trace with a free online barcode generator.