Barcodes are a fundamental part of modern inventory management, sales tracking, and logistical operations.

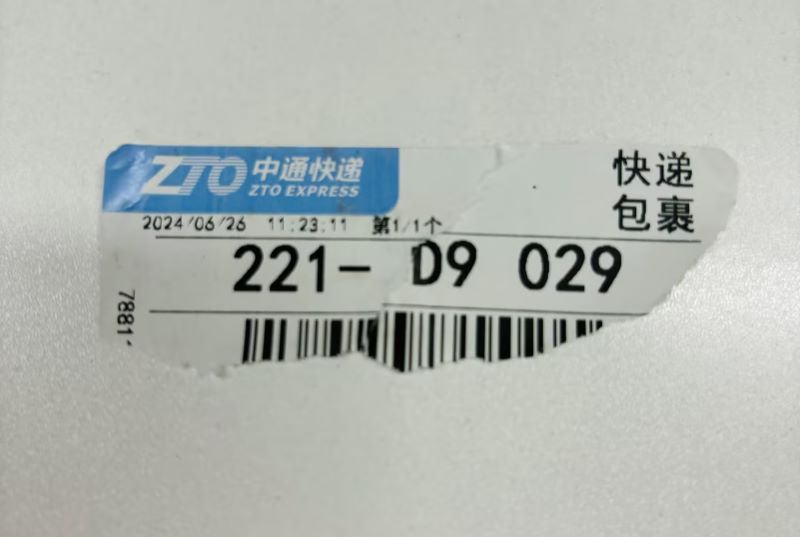

However, a common issue that many businesses face is the problem of a ripped barcode.

When a barcode is torn, damaged, or otherwise compromised, it can disrupt the entire scanning process, leading to inefficiencies and potential losses.

In this article, we will explore the causes of barcode damage, the impact on businesses, and practical solutions to mitigate these issues.

What Causes a Ripped Barcode?

Several factors can lead to a ripped barcode:

1. Handling and Transportation: During the movement of goods, barcodes can be subjected to rough handling. This includes dragging, dropping, or squeezing items, which can cause the labels to tear.

2. Environmental Factors: Exposure to moisture, extreme temperatures, and direct sunlight can weaken barcode labels, making them prone to tearing or fading.

3. Poor Quality Labels: Using low-quality materials for barcode labels can result in easy tearing. Investing in high-quality labels designed for durability can prevent this issue.

4. Improper Application: If barcode labels are not applied correctly, such as on uneven surfaces or over edges, they are more likely to get damaged.

Impact of Damaged Barcodes on Businesses

A barcoded damaged can have several negative consequences:

1. Scanning Errors: The primary issue with a ripped barcode is that it becomes unreadable by scanners. This leads to delays at checkout points, inventory mismanagement, and errors in tracking shipments.

2. Increased Costs: Damaged barcodes often mean that products need to be relabeled, which incurs additional costs for materials and labor.

3. Customer Dissatisfaction: Inefficient barcode scanning can lead to longer wait times for customers, causing frustration and potentially harming your business reputation.

4. Operational Inefficiencies: Inventory systems rely heavily on accurate barcode scanning. Damaged barcodes disrupt this flow, leading to incorrect stock levels and order fulfillment issues.

Will a Ripped Barcode Still Scan?

A ripped barcode may still scan if the damage is minimal and does not affect the critical parts of the barcode, such as the start, stop, and check digits.

However, significant tears or missing sections usually render the barcode unreadable, leading to scanning errors and operational delays.

It's best to inspect and, if necessary, replace damaged barcodes to ensure accurate scanning.

How to Handle Damaged and Ripped Barcodes?

1. Preventive Measures

● Choose High-Quality Labels: Invest in durable, high-quality barcode labels that can withstand various environmental conditions and handling processes.

● Proper Application Techniques: Ensure that labels are applied smoothly and securely on clean, flat surfaces. Avoid placing them over seams or edges.

● Protective Packaging: Use protective packaging to shield barcodes from physical damage during transportation and storage.

● Regular Inspection: Conduct regular inspections of barcode labels to ensure they remain intact and readable. This can help identify potential issues before they affect operations.

2. Remedial Actions

● Manual Entry: In cases where a barcode damaged cannot be scanned, employees can manually enter the barcode number. While this is time-consuming, it ensures the data is still captured.

● Reprinting Labels: For products with ripped barcodes, consider reprinting the barcode labels. This ensures continued readability and accurate tracking.

● Backup Labels: Place multiple barcode labels on different parts of the product or packaging. If one label is damaged, the others can still be scanned.

● Use of Technology: Implement advanced scanning technology that can read partially damaged barcodes. High-quality barcode scanners with enhanced decoding capabilities can sometimes read barcodes even if they are partially torn.

Case Study: Effective Management of Ripped Barcodes

Let's consider a hypothetical case of an online retailer. The company faced frequent issues with ripped barcodes during shipping. They decided to take several measures:

1. Upgraded Labels: Switched to high-quality, tear-resistant labels.

2. Improved Application Process: Trained staff on proper label application techniques.

3. Protective Packaging: Introduced new packaging materials that provided better protection for barcode labels.

4. Regular Monitoring: Implemented a system for regular inspection of barcodes.

These steps resulted in a significant reduction in damaged barcodes, improved scanning efficiency, and enhanced customer satisfaction.

In brief, dealing with a ripped barcode effectively is crucial for maintaining the efficiency and accuracy of your business operations.

By understanding the causes and impacts of barcode damage, and implementing both preventive and remedial measures, businesses can minimize disruptions and maintain smooth workflows.

For reliable barcode generation, visit an online barcode generator for free. Make the smart choice today and keep your barcode system robust and efficient.