As the global demand for cold chain logistics continues to rise, cold chain barcode technology has become essential for ensuring the safe transport and storage of temperature-sensitive products.

Cold chain logistics refers to the transportation and storage of goods that require temperature control, such as fresh food, pharmaceuticals, and vaccines. Even the smallest temperature fluctuation can compromise the quality of these products, making efficient tracking and management crucial.

By utilizing cold chain barcodes, businesses can monitor and track the temperature of goods at every step of the logistics process, ensuring that products remain safe and within required temperature ranges.

The Role of Cold Chain Barcodes in Logistics

With the rise of e-commerce and increasing consumer demand for safe, high-quality products, cold chain logistics has become more critical than ever.

The cold chain barcode technology is playing a key role in improving efficiency and ensuring safety in the transport of temperature-sensitive goods. Below, we explore how this technology works and its applications in different industries.

1. Fresh Food Logistics

In regions like North America, Europe, and Asia, the demand for fresh food is growing rapidly, and consumers expect the highest quality and freshness. Products like fruits, vegetables, meat, and seafood require strict temperature control during transit to maintain their quality and prevent spoilage. Cold chain barcodes are crucial for tracking these products from farm to table.

Retail giants like Amazon Fresh in the U.S., Tesco in the UK, and Hema Fresh in China rely on cold chain barcodes to track each product's journey. These barcodes store key information such as temperature requirements, production dates, and batch numbers. Consumers can scan the barcode to verify that their product has been kept at the correct temperature throughout the entire supply chain.

In warehouse management, scanning cold chain barcodes allows staff to ensure that products are stored under the right conditions. Automated systems can also generate real-time reports, minimizing errors and enhancing efficiency. If a product's temperature deviates from the required range, the system will trigger an alert to staff.

2. Pharmaceutical and Vaccine Transport

Cold chain barcodes are also essential in the pharmaceutical industry, especially when transporting temperature-sensitive drugs and vaccines. These products must remain within strict temperature ranges throughout the supply chain to maintain their efficacy.

For example, vaccine shipments are often equipped with temperature sensors integrated into the packaging. Cold chain barcodes work in conjunction with these sensors to monitor and record temperature data in real-time, ensuring compliance with regulations and preventing any temperature fluctuations that could compromise the product's integrity.

The use of barcodes in pharmaceutical logistics also ensures traceability, making it easier to identify potential issues and rectify them promptly.

How Cold Chain Barcodes Are Generated and Managed

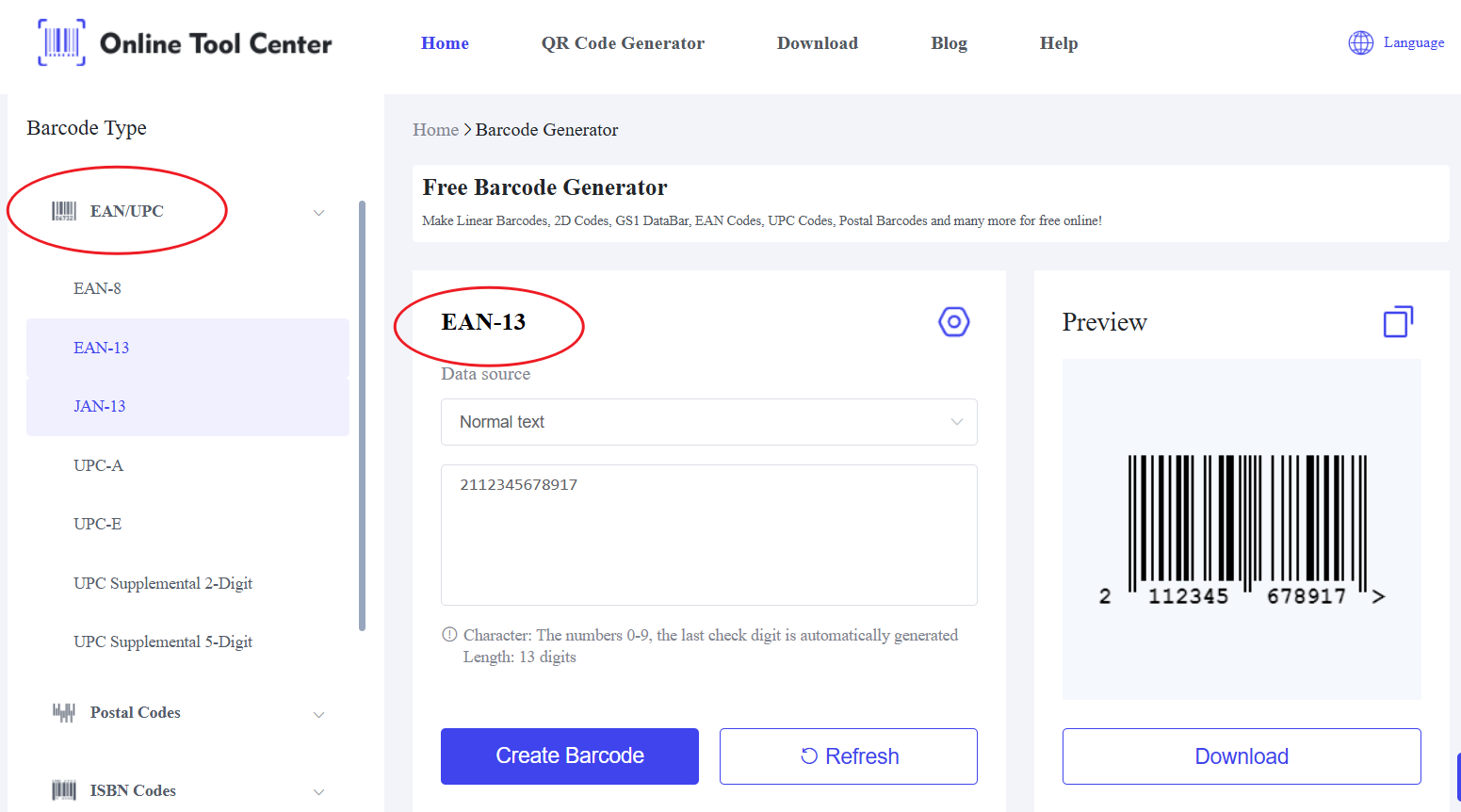

For cold chain logistics to run efficiently, businesses need reliable barcode generation and management systems. With the development of barcode technology, many tools and platforms now help companies generate barcodes that meet industry standards. Let's look at the process for generating and managing these barcodes.

1. Generating Cold Chain Barcodes

Choosing the right type of barcode is crucial in cold chain logistics. Different barcodes are used depending on the needs of the product and the data being tracked:

UPC and EAN Barcodes: These are simple, one-dimensional barcodes commonly used in retail. They contain basic product details like the name, production date, and batch number.

QR Codes and Data Matrix Codes: These two-dimensional barcodes can store more information, making them ideal for tracking multiple data points, such as temperature readings, humidity, production batches, and more. QR codes and Data Matrix codes are especially useful in cold chain logistics as they can store detailed real-time monitoring data.

2. Barcode Management and Tracking

A barcode is not just an identifier, it's a tool for data collection and tracking. Barcode management systems can integrate with warehouse management systems (WMS) and transportation management systems (TMS) to provide real-time data on product temperature, location, and shipping status.

By scanning cold chain barcodes, logistics personnel can quickly assess whether products are being transported within the required temperature range. If there's a deviation, the system will automatically alert staff to take corrective action. This integration helps businesses manage their cold chain processes efficiently and reduce the risk of product spoilage or loss.

Benefits of Using Free Barcode Generation Tools

For small and medium-sized enterprises (SMEs), using free barcode generation tools can be a cost-effective solution to streamline cold chain logistics. These online tools are easy to use and support multiple barcode types, including UPC, EAN, QR codes, and Data Matrix codes.

Additionally, many free barcode generators allow businesses to customize the barcode data, such as temperature and humidity information, so that it aligns with specific cold chain requirements. This customization ensures that the barcodes can be adapted to meet the needs of different industries and products.

Using barcode generators helps businesses maintain consistent quality and ensure that their products meet cold chain management standards. It also reduces the costs associated with developing proprietary barcode systems, making it an excellent solution for businesses looking to optimize their logistics processes.

Cold chain barcodes are a vital part of modern logistics, especially for industries that deal with temperature-sensitive products like food, pharmaceuticals, and vaccines. They provide a reliable way to track products throughout the supply chain, ensuring they stay within the required temperature range and are delivered in optimal condition.

Using barcode generation tools, businesses can quickly and easily create standardized barcodes, improving operational efficiency and reducing the risk of product spoilage or loss.

If you're looking for a simple, effective solution for generating cold chain barcodes, check out this free barcode generator tool to optimize your cold chain logistics.