A Complete Guide to MRP Barcode Stickers for Retailers

Barcodes have become indispensable tools in the retail industry, offering efficient and reliable product management.

One crucial type of label in the retail landscape is the MRP barcode sticker. It combines the Maximum Retail Price (MRP) with a scannable barcode, ensuring seamless transactions and inventory management while maintaining price transparency for consumers.

This article will provide a detailed overview of MRP stickers with barcode, their role in the retail industry, the process of generating them, and the best practices for using them effectively.

What is an MRP Barcode Sticker?

An MRP barcode sticker is a label that displays two critical pieces of information:

MRP (Maximum Retail Price): The maximum price a consumer can be charged for a product.

Barcode: A machine-readable code that encodes product information, enabling quick scanning at checkout.

These stickers are commonly found on retail products, ensuring both compliance with pricing laws and enhancing operational efficiency by automating product identification and pricing.

Barcodes on MRP stickers typically store data like Global Trade Item Numbers (GTIN), SKU numbers, or custom identifiers, making them essential for inventory control and pricing consistency across multiple retail locations.

Example of an MRP Barcode

Barcode Type: EAN-13

Sample Data in the Barcode:

GTIN (Global Trade Item Number): 8901234567890

MRP: ₹299

Batch Number: B1234

Expiry Date: 12/2024

Visible on the Sticker:

Maximum Retail Price (MRP): ₹299

Product Name: Shampoo 500ml

Batch No.: B1234

Expiry Date: 12/2024

Explanation:

In this MRP barcode example:

The barcode (EAN-13) encodes the unique GTIN (8901234567890) for product identification. This number allows retailers to pull up product information from their database during checkout or inventory management.

MRP (₹299) is printed visibly on the sticker, ensuring consumers know the maximum price.

Batch number and expiry date are also included in the text, helping with product traceability and ensuring proper stock rotation for time-sensitive goods like food or cosmetics.

The barcode itself doesn't always carry the MRP but links to product information in the retailer's system where the price is retrieved.

Importance of MRP Barcode Stickers in Retail

1. Compliance with Pricing Regulations

In many countries, it is legally required for products to display their MRP. By using an MRP barcode sticker, retailers ensure that they comply with local and national pricing regulations. This is especially crucial in markets like India, where MRP laws are strictly enforced to prevent price gouging and ensure consumer protection.

2. Efficiency in Retail Operations

Barcodes allow for quick and accurate scanning of product information at checkout, reducing human error and accelerating transaction times. When the barcode is integrated with the MRP, it simplifies the entire sales process, as prices are automatically fetched from the system.

3. Streamlined Inventory Management

Barcodes enable real-time tracking of stock levels, ensuring that retailers can maintain accurate records of products available in stores and warehouses. MRP stickers with barcodes also help automate reordering systems, reducing the risk of stockouts or overstocking.

Types of Barcodes Used on MRP Stickers

Various types of barcodes can be used on MRP barcode stickers, depending on the region and product requirements. The two most commonly used barcode formats in retail are UPC and EAN, both of which are recognized globally and support efficient product identification and pricing.

1. UPC (Universal Product Code)

Example: A UPC barcode for a bottle of shampoo might look like this:

GTIN (UPC-A): 036000291452

In this case, the 12-digit number encodes product-specific information that can be scanned at checkout or used for inventory tracking.

Usage: UPC barcodes are standard in the U.S. and Canada, and commonly found on retail products like food, beverages, and consumer goods. These barcodes are often accompanied by visible MRP information on the sticker.

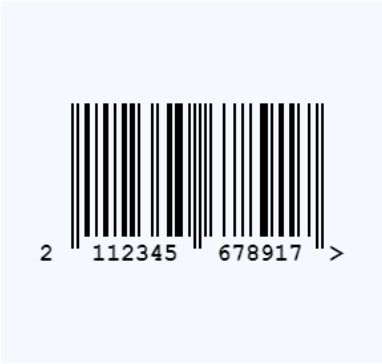

2. EAN (European Article Number)

Example: For a packet of cereal sold in Europe, the EAN barcode might appear as:

GTIN (EAN-13): 4006381333931

This 13-digit number uniquely identifies the product across international markets.

Usage: EAN-13 barcodes are used globally for retail products and can contain the same basic product information as UPC codes. The sticker will often display the MRP alongside the EAN barcode.

Both UPC and EAN barcodes are efficient tools for product management, allowing retailers to integrate pricing, inventory control, and customer transactions seamlessly. However, in many regions, the MRP is printed separately on the sticker and is not encoded in the barcode itself.

How to Generate MRP Barcode Stickers?

Creating MRP barcode stickers is simpler than you might think. Here's a step-by-step process for generating them using an online barcode generator:

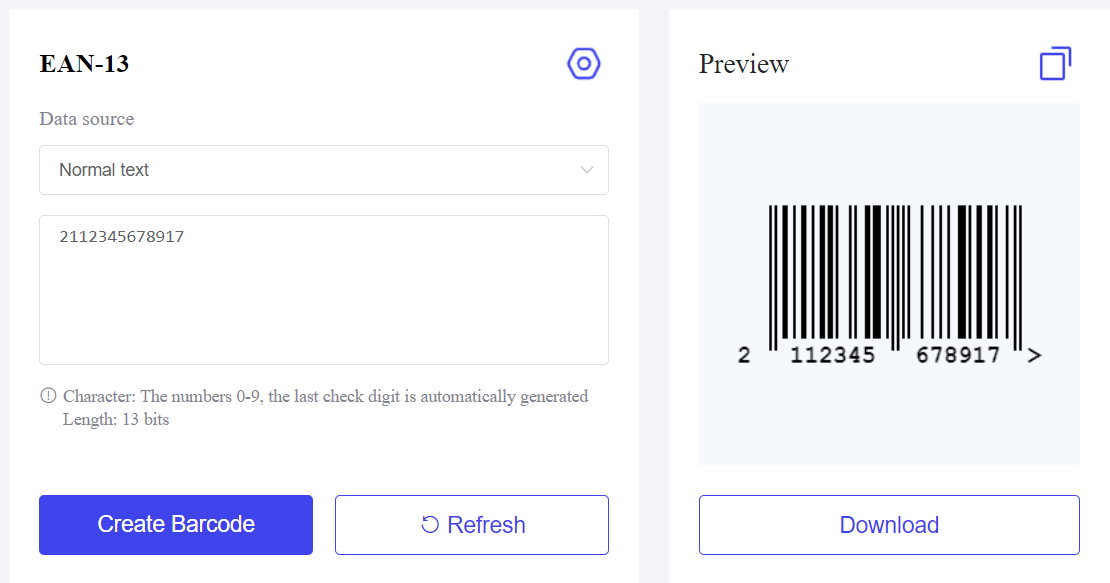

Step 1: Choose the Barcode Type

First, determine the barcode type suitable for your products. For retail items, UPC or EAN-13 are the most common choices. If your products are sold internationally, it's advisable to opt for EAN-13 for broader compatibility.

Step 2: Input Product Information

Input key product details into the barcode generator, including the Global Trade Item Number (GTIN) or any unique identifiers used by your business. If you're using a QR code, you can embed additional details such as links to product websites, promotions, or warranty information.

Step 3: Include MRP Data

Add the MRP to the sticker design. This should be prominently displayed to ensure visibility and compliance with local laws. Some businesses also print additional information like batch numbers, manufacturing dates, or expiration dates.

Step 4: Customize the Sticker

To maintain brand consistency, you may want to include logos, product descriptions, or promotional messages on the MRP barcode sticker. Be sure that the barcode remains scannable, with adequate white space around it to ensure high readability.

Step 5: Print and Apply

Once the sticker design is complete, print it using a barcode printer on durable, high-quality sticker material. Ensure the printed barcode adheres to industry standards so that it can be easily scanned by any POS system.

You can use an online tool like the barcode generator to create MRP barcode stickers quickly and efficiently.

Best Practices for MRP Barcode Stickers

When designing and implementing MRP barcode stickers, there are several best practices to follow:

1. Ensure Legibility

The MRP should be printed in a clear, bold font, making it easy for customers to see. Barcodes should also be large enough to be scanned without difficulty, even from a distance.

2. Maintain Barcode Integrity

The barcode must remain free from smudges, tears, or distortions. Poor-quality printing or damaged stickers can lead to scanning issues, causing delays at checkout and disrupting inventory tracking.

3. Use High-Quality Materials

Invest in durable sticker materials to ensure that your MRP barcode stickers can withstand handling during shipping and on store shelves. Opt for water-resistant or scratch-proof materials where necessary.

4. Regular Updates

Ensure that barcodes and MRP values are updated regularly, particularly when prices or regulations change. Outdated price information might cause compliance concerns and customer displeasure.

Regulatory compliance, enhanced customer trust, and operational efficiency are just a few advantages of integrating MRP barcode stickers into your retail operations.

By using an online barcode generator, you can easily create customized MRP stickers for all your products.

By ensuring clear pricing and integrating efficient barcode technology, retailers can streamline their processes and enhance both customer satisfaction and business performance.