Barcodes streamline processes by encoding information that can be quickly and accurately read by scanners.

However, an unscannable barcode can bring these systems to a halt, causing delays and errors. Understanding why barcodes become unscannable and knowing how to fix these issues is important for maintaining operational efficiency.

This article explores the common causes of bad barcodes and provides actionable solutions to ensure your barcodes remain readable.

What makes a barcode unscannable?

Common Causes of Unscannable Barcodes:

1. Poor Print Quality

Barcodes must be printed with sharp, clear lines to ensure they can be scanned accurately. Low-quality printers, depleted ink or toner cartridges, and improper printer settings can result in unscannable barcodes.

Faint, smudged, or blurred barcodes are particularly problematic, as they prevent a barcode scanner from distinguishing the necessary bars and spaces.

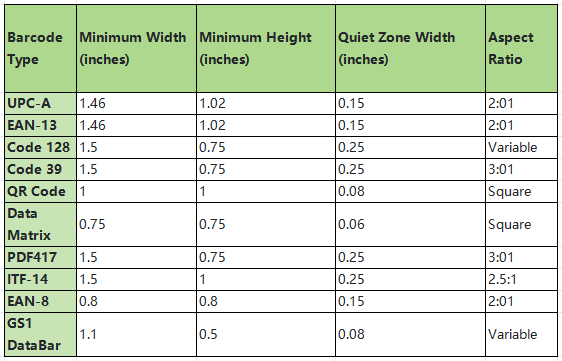

2. Incorrect Barcode Size and Dimensions

Barcodes must conform to specific barcode size and dimension requirements to be readable.

Barcodes must adhere to specific size and dimension requirements to be readable. If a barcode is too small, the scanner might not capture all the details, while a barcode that is too large might not fit within the scanner's field of view.

Adhering to standardized dimensions ensures that barcodes can be scanned efficiently in various environments.

3. Inadequate Contrast

Scanners rely on contrast to differentiate between the bars and spaces of a barcode. Printing a barcode in colors that do not contrast well with the background can result in an unreadable barcode.

The most reliable combination is black bars on a white background, but if other colors are used, they must provide sufficient contrast to be effective.

4. Damage to the Barcode

Physical damage such as scratches, smudges, or tears can render a barcode unscannable. This is a common issue in environments where barcodes are subject to rough handling or exposure to elements like moisture and dirt.

Protecting barcodes from such damage is essential for maintaining their readability.

5. Improper Barcode Placement

The placement of a barcode on a product or packaging affects its scannability. Barcodes placed on curved surfaces, corners, or areas where they can be obscured by other packaging elements are more challenging to scan.

Barcodes should be placed on flat, unobstructed surfaces to ensure they can be easily read.

6. Wrong Barcode Format

Different industries and applications require specific barcode formats. Using the incorrect format can lead to unreadable barcodes.

For example, using a UPC code where an EAN code is required can cause scanning issues. It is crucial to select the appropriate barcode format for your specific application to avoid these problems.

How to Fix an Unscannable Barcode?

1. Ensure High Print Quality

To ensure high-quality barcodes, use barcode printers capable of producing sharp, clear lines.

Regularly maintain the printer, replace ink or toner cartridges as needed, and adjust printer settings to optimize print quality.

High print quality prevents common issues such as faint or smudged barcodes, which are often unscannable.

2. Adhere to Size and Dimension Standards

Follow industry guidelines for barcode sizes and dimensions. Barcodes should neither be too small to be detected by scanners nor too large to fit within the scanner's view.

Standardizing barcode sizes ensures they are easily readable across various scanning environments.

3. Improve Contrast

Ensure there is a stark contrast between the barcode and its background.

The most effective combination is black on white, but other color combinations can work as long as they provide sufficient contrast.

Avoid using colors that blend into the background, as this can result in unreadable barcodes.

4. Protect the Barcode

Implement protective measures such as lamination or applying a clear, durable coating to shield barcodes from physical damage.

This is particularly important in environments where barcodes are exposed to rough handling or adverse conditions. Protecting barcodes from scratches, smudges, and tears ensures they remain scannable.

5. Optimal Placement

Place barcodes on flat, smooth surfaces where they are easily accessible to scanners.

Avoid placing barcodes on curved surfaces, corners, or areas where they might be obscured by other packaging elements. Proper placement ensures that barcodes can be scanned quickly and efficiently.

6. Use the Correct Barcode Format

Select the appropriate barcode format for your specific application. Research industry standards and requirements to ensure you are using the correct format.

Using the correct barcode format prevents scanning issues and ensures compatibility with various scanning systems.

7. Verify and Test Barcodes

Regularly verify and test your barcodes with scanners. This helps identify potential issues before the barcodes are used in real-world applications.

By catching and addressing problems early, you can ensure that all barcodes are scannable and avoid disruptions in operations.

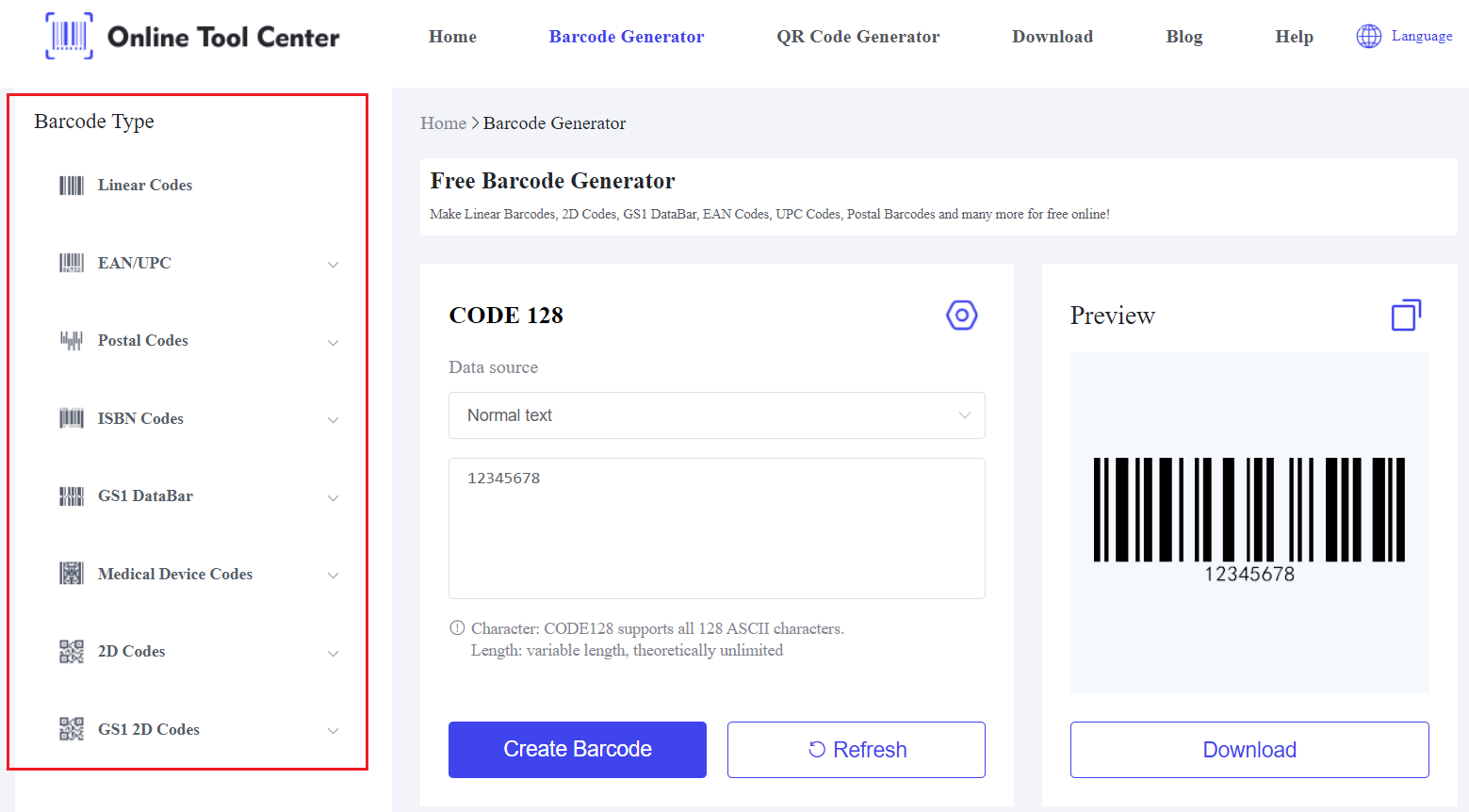

8. Utilize a Reliable and Free Barcode Generator

Use a reliable and free barcode generator to create accurate and high-quality barcodes. A reliable generator ensures your barcodes meet industry standards and reduces the risk of creating bad barcodes.

All in all, an unscannable barcode can cause significant operational disruptions. By understanding the common causes of bad barcodes and implementing the solutions provided, you can ensure your barcodes remain readable and effective.

Regular maintenance, proper printing practices, and using a reliable and free barcode generator are key steps in preventing unreadable barcodes.

For high-quality, scannable barcodes, use the free barcode generator!