Barcodes have become an integral part of the food industry, revolutionizing the way businesses manage inventory, ensure food safety, and enhance efficiency.

In this article, we will explore the various uses and benefits of barcodes in the food industry, learn the different types of barcodes, and provide insights into their implementation.

What is the Barcode for Foods?

Barcodes on foods are typically represented by a series of parallel lines and spaces, that store essential information about the product.

These codes are scanned at various points in the supply chain to track inventory, ensure accurate pricing, and facilitate quick and efficient checkouts.

Commonly used barcodes in the food industry include the Universal Product Code (UPC) for retail products, providing quick and accurate scanning at checkout.

QR codes are used to offer detailed product information and interactive content accessible via smartphones.

For fresh foods, the GS1 Databar is utilized to enhance traceability and food safety by including additional data like expiration dates and batch numbers.

Types of Barcodes Used in the Food Industry

1. UPC (Universal Product Code)

The UPC is widely used for retail products and is recognized globally. It consists of 12 numeric digits that are uniquely assigned to each product.

The main advantage of UPCs is their simplicity and widespread acceptance. However, they have limitations in terms of the amount of information they can store.

2. QR Codes

QR Codes are two-dimensional barcodes that can store a significant amount of data, including URLs, product information, and more.

They are increasingly used in the food industry for purposes such as providing detailed product information, promotional content, and traceability.

For example, a consumer can scan a QR code on a food package to access information about its nutritional content, origin, and recipes.

3. GS1 Databar

The GS1 Databar can hold more information than a traditional barcode and is used for fresh foods, coupons, and product serialization.

This type of barcode supports additional data such as expiration dates and batch numbers, which are essential for perishable items.

Compared to UPCs, GS1 Databars provide enhanced capabilities for product tracking and management.

Benefits of Barcode for Foods

1. Improved Inventory Management

Barcodes streamline the inventory management process by providing accurate and real-time data on stock levels.

For example, a grocery store can use barcode scanning at the checkout to update inventory levels instantly, ensuring that the stock is accurately reflected in its system.

2. Enhanced Traceability and Food Safety

Traceability is crucial in the food industry for ensuring food safety and compliance with regulations. Barcodes enable detailed tracking of food products from the source to the end consumer.

A notable case is the implementation of barcodes by Walmart, which enhanced their ability to track produce back to the farm, improving food safety and transparency.

3. Cost Reduction and Efficiency

By automating data entry and reducing manual labor, barcodes can lead to substantial cost savings.

For instance, a food distributor using barcode systems can reduce the time spent on inventory counts and order processing, leading to lower operational costs.

How to Create a Barcode for Your Food Product?

Step 1: Choose the Right Barcode Type

Selecting the appropriate barcode type for your food product depends on various factors, including the product category, packaging size, and the amount of information you need to encode.

Step 2: Obtain a Barcode Number

To create a barcode, you need a unique product number. For global trade, it’s recommended to obtain a Global Trade Item Number (GTIN) from GS1, an organization that sets standards for barcodes worldwide.

Registering with GS1 ensures that your barcode is unique and recognized globally.

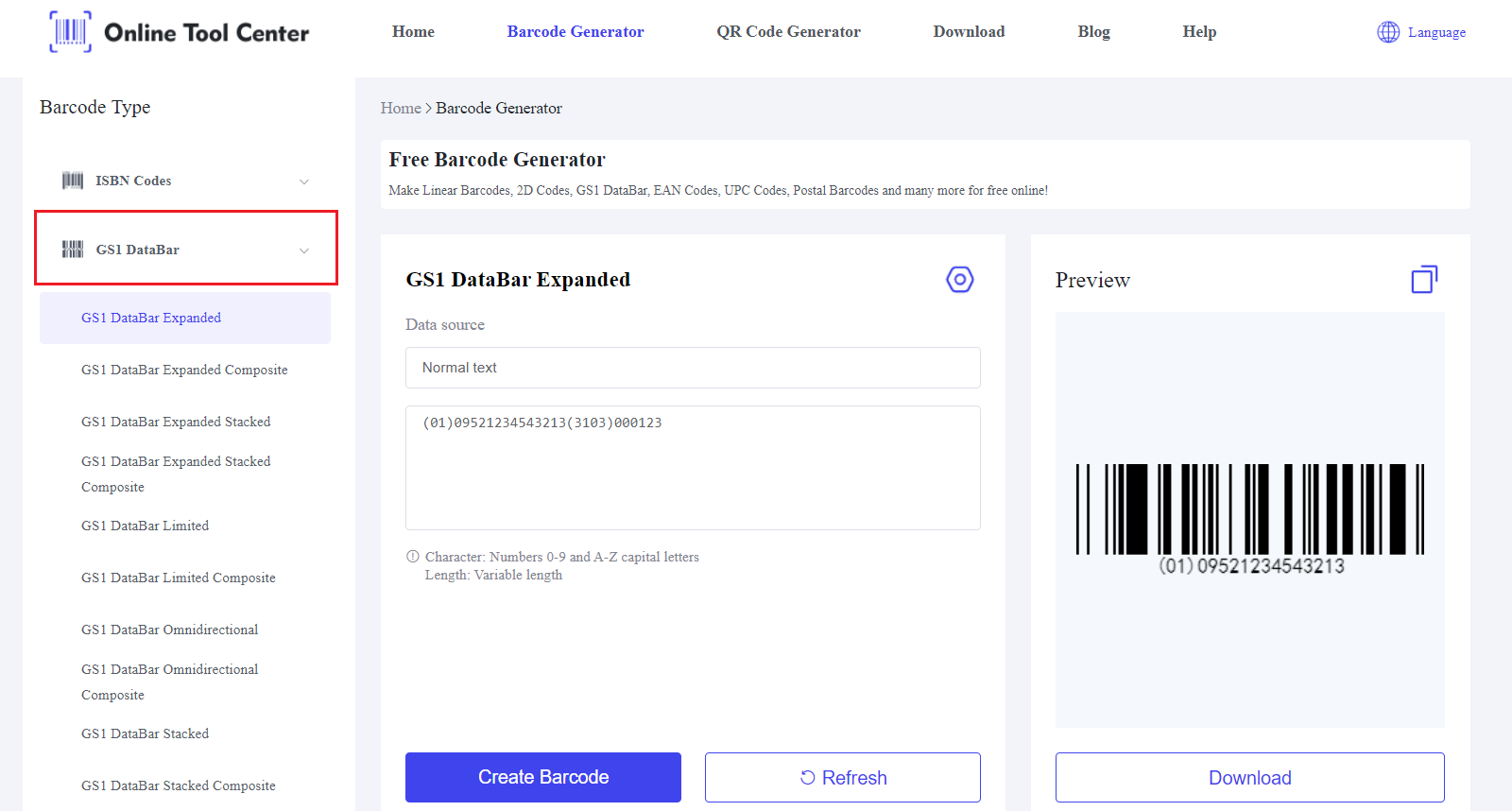

Step 3: Generate the Barcode for Food

Once you have your GTIN, you can generate the barcode. A free barcode generator can help with this.

Enter your GTIN and select the desired barcode type to create your barcode image.

Step 4: Integrate the Barcode into Your Packaging

After generating the barcode, the next step is to incorporate it into your product packaging.

Ensure the barcode is placed in a clear, unobstructed area on the package to facilitate easy scanning.

The size and placement of the barcode are critical for readability, so follow industry guidelines for barcode dimensions and spacing.

Step 5: Test the Barcode

Before printing large quantities, test the barcode to ensure it scans correctly. Use a handheld barcode scanner or a smartphone app to verify that the barcode retrieves the correct information.

Testing helps to catch any errors and ensures the barcode will function properly in retail environments.

Step 6: Implement Barcode Systems

Integrating barcodes into your inventory and point-of-sale systems is essential for maximizing their benefits.

Update your inventory management software to include barcode scanning capabilities, which will streamline processes like stock taking, order processing, and sales tracking.

FAQs

1. What is the barcode on food called?

The barcode on food products is commonly referred to as the UPC (Universal Product Code), though other types like QR codes and GS1 Databars are also used.

2. How to create a food barcode?

Creating a food barcode involves selecting the appropriate barcode type, using a barcode generator, and printing the barcode on product labels or packaging.

3. What information is in a food barcode?

A food barcode typically includes product identification details, price, batch number, and sometimes additional information like expiration date and manufacturer details.

Wrapping up, barcodes for food play an important role in the food industry by improving inventory management, enhancing traceability, and reducing costs.

Explore the possibilities today and enhance your operational efficiency with a free barcode generator.