What is a Barcode?

A barcode is a visual representation of data that can be scanned and read by machines. It typically appears as a series of parallel lines of varying widths.

Barcodes are categorized into two types: 1D (One Dimensional) and 2D (Two Dimensional). The 1D barcodes, such as UPC and EAN, are the most commonly seen in retail settings. They store information horizontally.

On the other hand, 2D barcodes like QR codes can store information both horizontally and vertically, allowing them to hold a variety of data types and larger amounts of information.

Barcodes are extensively used in retail for pricing and inventory. In healthcare, they manage patient records and medication tracking. In logistics, barcodes track shipments and streamline the supply chain processes.

What is RFID?

RFID uses electromagnetic fields to automatically identify and track tags attached to objects. The technology was developed to allow items to be tracked over distances without the need for a direct line of sight.

An RFID system consists of three components: a tag, a reader, and an antenna. Tags can be active, powered by a battery; passive, powered by the reader's electromagnetic field; or semi-passive, which uses a battery to run the tag's circuitry while communicating by drawing power from the reader.

RFID technology finds use in industries where tracking the movement and status of goods in real-time is crucial, such as in manufacturing for tracking assets and in logistics for managing warehouse inventories.

How do Barcodes and RFID Work?

1. How Barcodes Work?

The basic technology behind barcodes involves optical signals being reflected from the printed barcode to a scanner. The scanner reads these signals, decodes the information, and transmits it to a computer system.

Barcode systems require a barcode scanner, which uses a light source, a lens, and a light sensor to translate optical impulses into electrical ones. Most commonly, laser scanners or CCD (Charge Coupled Device) readers are used.

2. How RFID Works?

The basic RFID system includes tags, readers, and antennas. Tags store the data; readers send signals to and receive signals from these tags; antennas boost the reader's ability to detect tags.

RFID tags transmit data to the reader via radio waves. The reader then decodes this information and sends it to the backend systems for processing and integration.

RFID vs Barcode

What is the difference between RFID and barcode?

1. Cost Comparison

Setting up a barcode system typically involves lower upfront costs compared to RFID. Barcode equipment and materials are less expensive, and the technology is easier to implement.

However, RFID tags can be more cost-effective over time for larger systems due to their reusability and the labor savings they provide.

Barcode scanners and printers are generally more affordable than RFID systems, which require more complex and costly components such as readers and programmable tags.

2. Efficiency and Reliability

RFID usually offers faster processing speeds and higher read rates compared to barcode systems, which can be hindered by physical damage to the barcode label or improper scanning angles.

RFID tags are typically more robust and can be read through different environmental conditions that might render barcodes unreadable, such as dirt, dust, and moisture.

3. Range and Scalability

RFID systems have a greater range of detection, capable of reading multiple tags within a range of up to several meters. In contrast, barcodes must be scanned individually and within proximity.

RFID offers superior scalability for large-scale operations, supporting massive numbers of simultaneous reads and easy integration into complex logistic operations. Barcodes, while effective on a smaller scale, can become cumbersome in larger setups.

4. Application Suitability

● Best Use Cases for Barcodes

Barcodes are ideal for smaller businesses, retail operations, or situations where line-of-sight scanning is feasible and cost constraints are significant.

● Ideal Scenarios for RFID Utilization

RFID shines in environments requiring rapid, multiple item scans and where environmental conditions may interfere with label integrity, such as in manufacturing and logistics.

Pros and Cons of Barcodes and RFID

1. Advantages of Barcodes and RFID

● Barcodes:

Cost-effective for initial setup

Simple to implement and integrate

Wide recognition and compatibility with existing systems

● RFID:

High efficiency and speed in data collection

Effective in challenging environmental conditions

Enhances real-time tracking and inventory management

2. Disadvantages of Barcodes and RFID

● Barcodes:

Limited data storage capacity

Susceptible to physical damage and environmental conditions

Requires line-of-sight for scanning

● RFID:

Higher initial costs and complexity

Potential privacy concerns with tag tracking

Interference issues from metals and liquids

Industry Case Studies of Barcodes and RFID

1. Barcode in Retail

In retail settings, barcodes have transformed inventory management and checkout processes. A prominent retail chain implemented a barcode system across its 200 stores, resulting in a 30% reduction in checkout times and significant improvements in inventory accuracy.

2. RFID in Logistics

A major logistics company adopted RFID technology to track shipments across its supply chain. This implementation led to a 25% improvement in delivery times and a 40% reduction in lost items, showcasing the impact of efficient tracking technologies.

Which one Should I Choose Barcode or RFID?

Choosing between barcode and RFID technology depends primarily on your specific business needs and budget. Barcodes are cost-effective and simpler to implement, making them ideal for businesses with straightforward, small-scale tracking needs or limited budgets.

They work well in retail environments for tasks like pricing and inventory management.

On the other hand, RFID offers greater efficiency and scalability, suited for larger operations or situations where rapid, bulk scanning and environmental durability are required, such as in logistics and manufacturing.

If your operation demands high-speed processing and can justify the initial higher costs, RFID might be the more suitable choice.

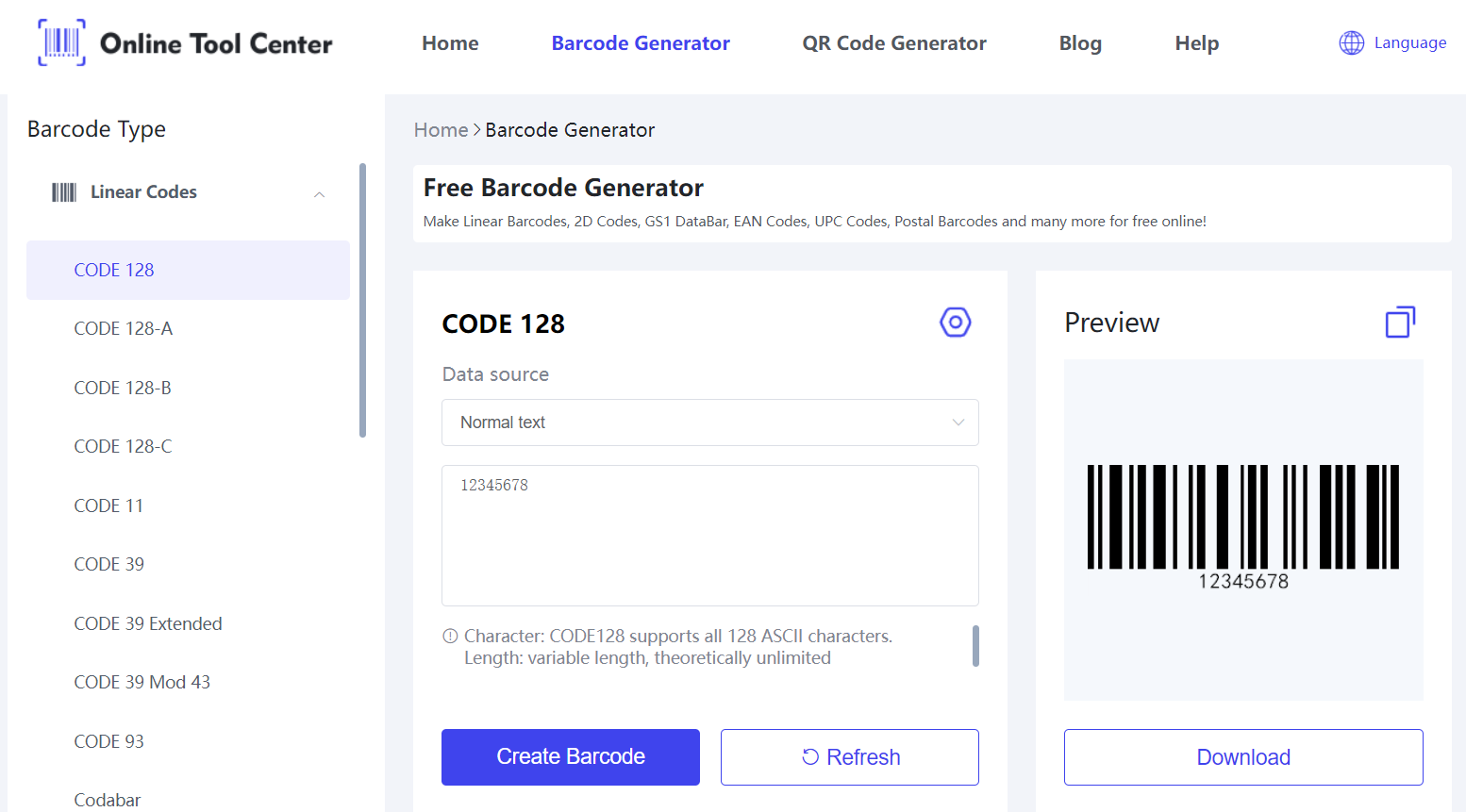

In conclusion, choosing between barcode and RFID technology should align with your business needs. For cost-effectiveness and ease of use, barcodes are ideal, and our barcode generator can support your operations efficiently.

FAQs

1. What is the main difference between barcode and RFID technology?

The main difference lies in the method of data retrieval and range; barcodes require optical scanning, while RFID uses radio frequency for distant, multiple-tag readings.

2. Which is more cost-effective in the long run, barcodes or RFID?

For large-scale operations, RFID can be more cost-effective due to lower labor costs and higher efficiency, while barcodes are more suitable for smaller, budget-conscious businesses.