In manufacturing and logistics, accurate and reliable traceability is essential. One technology that stands out for its durability and efficiency is the DPM code.

This article explores DPM codes in detail, focusing particularly on the DPM Data Matrix format, its benefits, applications, and the best practices for implementation.

What is a DPM Code?

A DPM code (Direct Part Marking code) is a type of barcode that is permanently marked onto the surface of a part or product.

Unlike traditional barcodes printed on labels and then attached to products, DPM barcodes are integrated into the product, making them extremely durable and resistant to various environmental factors.

Direct part marking can be done using several methods, including:

● Laser Engraving: Utilizes a focused laser beam to etch the barcode onto the surface. It is suitable for a wide range of materials, including metals, plastics, and ceramics.

● Dot Peen Marking: Uses a stylus to create a series of dots that form the barcode. It is ideal for hard materials such as metals.

● Electrochemical Etching: Involves using an electrolyte solution and an electric current to etch the barcode onto conductive materials.

Understanding DPM Data Matrix Codes

The DPM Data Matrix code is a two-dimensional barcode that can store a significant amount of data in a small footprint.

This makes it particularly suited for DPM codes, where space can be limited.

The Data Matrix code consists of black and white cells arranged in a square or rectangular pattern, which can encode up to 3,116 characters.

Key Features of DPM Data Matrix Codes

● High Data Density: The DPM Data Matrix code can store large amounts of information, making it ideal for parts that require detailed traceability information.

● Error Correction: It incorporates robust error correction algorithms (ECC 200), which ensure that the code can be read accurately even if it is partially damaged.

● Scalability: The size of the Data Matrix code can be adjusted to fit small surfaces, allowing for marking on tiny components.

● Durability: When marked using methods like laser engraving, the Data Matrix code can withstand harsh environmental conditions, including extreme temperatures, chemicals, and physical wear.

Benefits of Using DPM Codes

The use of DPM codes offers several significant advantages:

● Durability: Since DPM barcodes are part of the product, they are more resistant to wear and tear compared to traditional labels. This ensures that the codes remain readable throughout the product's lifecycle, even in harsh environments.

● Traceability: DPM codes provide a reliable means of tracking parts and components from manufacturing to end-of-life. This is especially important in industries like aerospace, automotive, and medical devices, where traceability is critical for safety and compliance.

● Space Efficiency: DPM Data Matrix codes can store a large amount of information in a small space. This is particularly useful for marking small parts or components where traditional labels might not fit.

● Cost-Effective: While the initial investment in marking equipment can be significant, the long-term benefits of direct part marking often outweigh these costs. There is no need for consumables like labels or ink, and the durability of the marks reduces the need for re-marking or re-labeling.

Applications of DPM Data Matrix Codes

DPM Data Matrix codes are widely used across various industries due to their durability and capacity to store extensive information. Some key applications include:

● Aerospace: Aircraft components often require permanent identification to comply with regulatory standards and ensure safety. DPM Data Matrix codes can withstand the harsh conditions experienced in aerospace environments.

● Automotive: In the automotive industry, DPM codes are used to track parts through production, assembly, and service. This helps in managing recalls and verifying authenticity.

● Medical Devices: DPM Data Matrix codes are essential for medical devices, providing critical traceability from manufacturing to patient use. The codes must endure sterilization processes and remain readable.

● Electronics: Small electronic components, such as circuit boards and chips, benefit from DPM Data Matrix codes due to their compact size and high data capacity, facilitating inventory management and quality control.

Best Practices for Implementing DPM Data Matrix Codes

Implementing DPM codes requires careful planning and execution to ensure their effectiveness and durability. Here are some best practices to consider:

1.Select the Appropriate Marking Method

The choice of marking method (laser engraving, dot peen, or electrochemical etching) depends on the material of the part and the environmental conditions it will face.

Laser engraving is versatile and suitable for many materials, while dot peen is excellent for metals.

2.Optimize Code Design

Ensure that the DPM Data Matrix code is designed to be easily readable.

This includes considering the size, contrast, and placement of the code on the part. Testing different configurations can help achieve the best results.

3.Ensure Readability

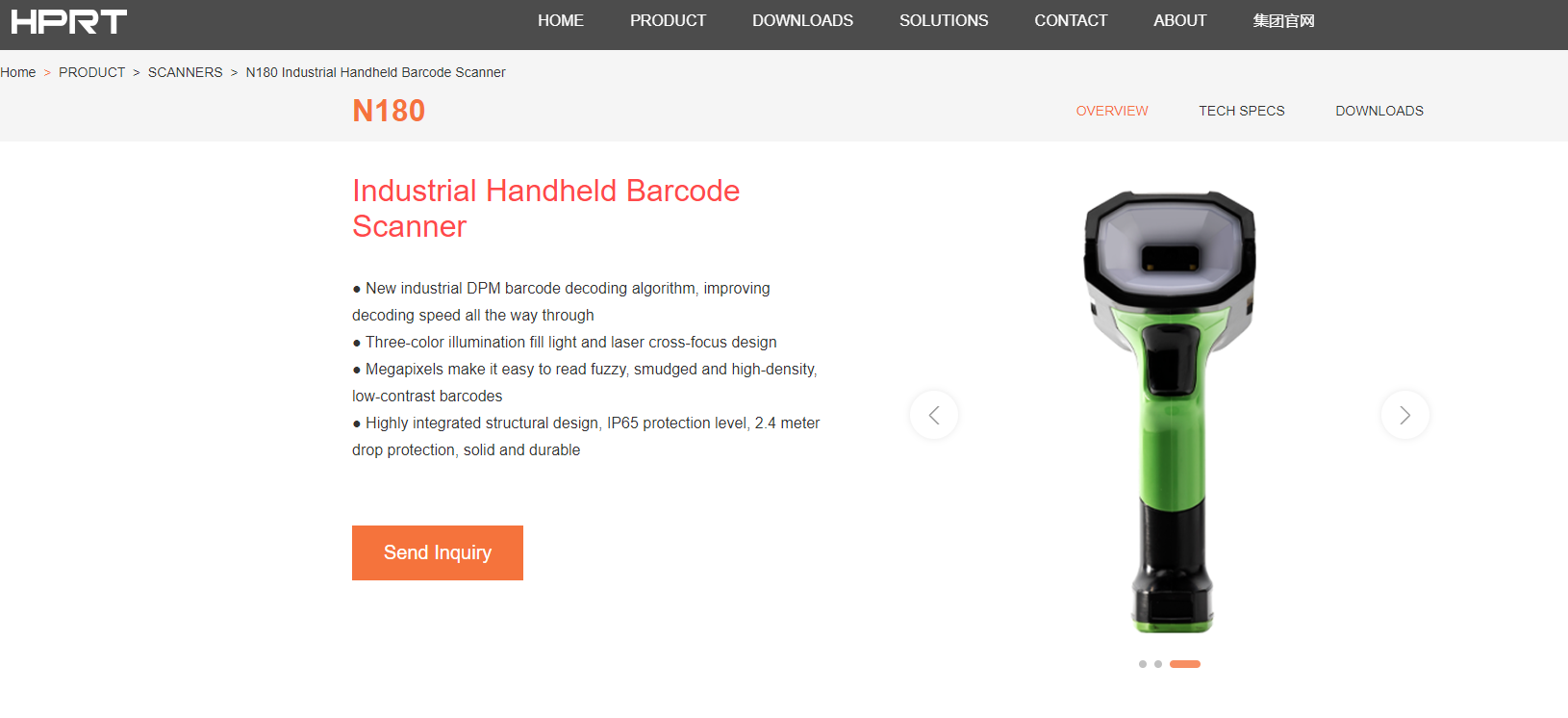

Use an industrial handheld barcode scanner capable of reading DPM Data Matrix codes.

Scanners with advanced decoding algorithms are often necessary to handle the intricacies of direct part marks.

4.Regular Quality Control

Implement a quality control process to regularly inspect marked codes and ensure they remain readable over time.

This is particularly important for parts exposed to harsh conditions.

5.Training and Documentation

Train your staff on the importance of DPM codes and the correct procedures for marking and reading them.

Maintain detailed documentation of marking processes and standards to ensure consistency.

Overall, the integration of DPM codes, particularly DPM Data Matrix codes, offers significant advantages in terms of durability, traceability, and efficiency.

These codes are essential for industries that require precise and reliable part identification throughout the product lifecycle.

Implementing DPM codes effectively involves selecting the right marking method, optimizing code design, ensuring readability, and maintaining quality control.

By adhering to these best practices, businesses can enhance their traceability processes and meet regulatory requirements.

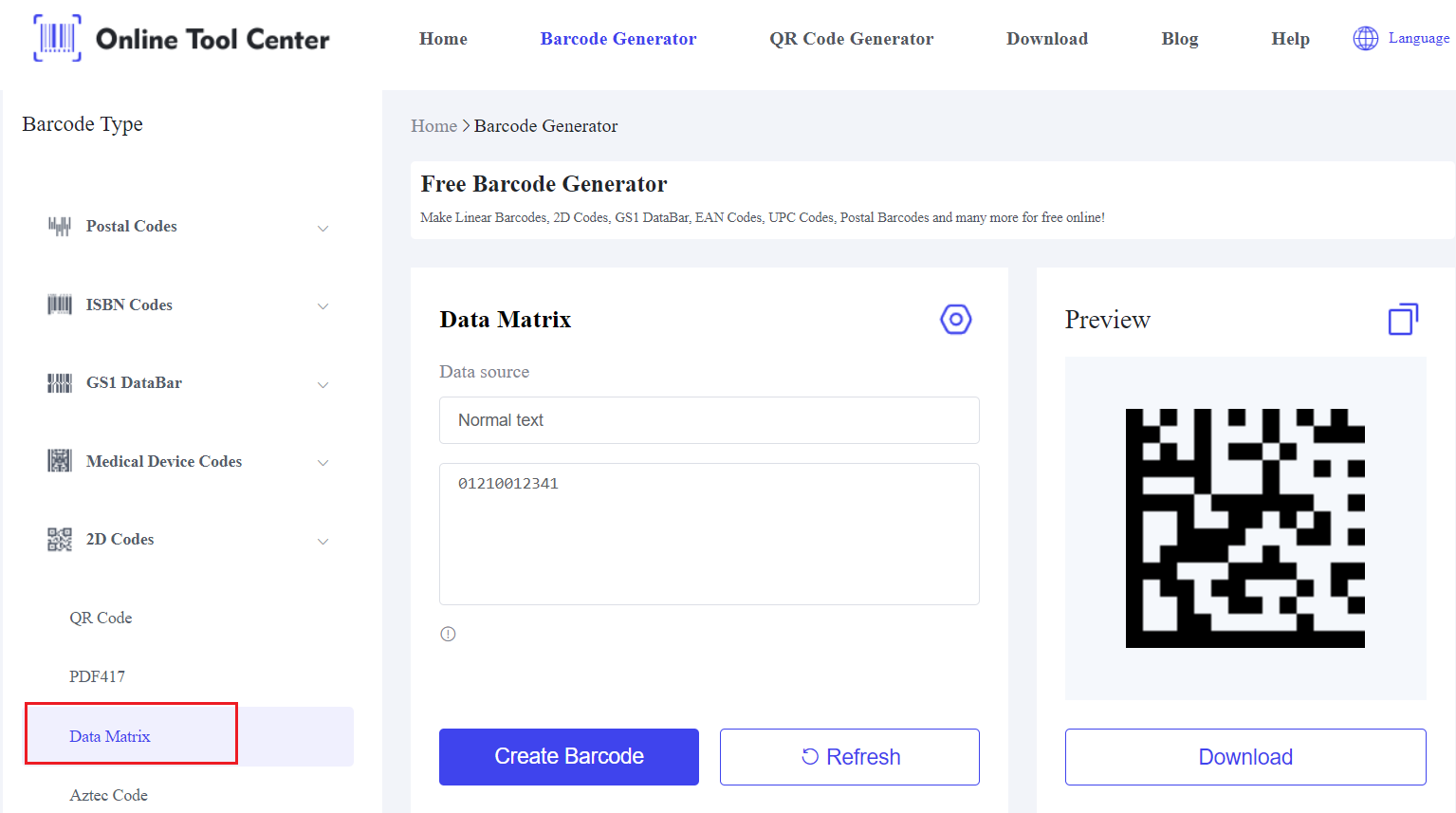

Start leveraging the power of Data Matrix with our barcode generator!