A backroom barcode generator is a vital tool that can streamline this process, reducing errors and saving time.

This article will explain what a backroom barcode generator is, how to use it, and its applications in inventory management.

What is a Backroom Barcode Generator?

A backroom barcode generator is a software tool designed to create barcodes for inventory items. These barcodes are essential for tracking products, managing stock levels, and ensuring accurate data entry.

By generating unique barcodes for each item, businesses can maintain a well-organized inventory system, making it easier to locate products and track their movement.

Barcodes consist of a series of lines and spaces that represent information readable by barcode scanners. This information typically includes product details such as the item's name, price, and stock-keeping unit (SKU).

A backroom barcode generator simplifies the process of creating these barcodes, allowing businesses to label their inventory efficiently.

Why Use a Backroom Barcode Generator?

Using a backroom barcode generator streamlines inventory management by providing a fast, accurate, and efficient method for labeling and tracking items, reducing human error, and enhancing organization within the backroom or warehouse.

This tool integrates seamlessly with inventory systems, improving stock control, order fulfillment, and overall productivity while being cost-effective and scalable as your business grows.

How to Use a Backroom Barcode Generator?

Here are the steps to follow:

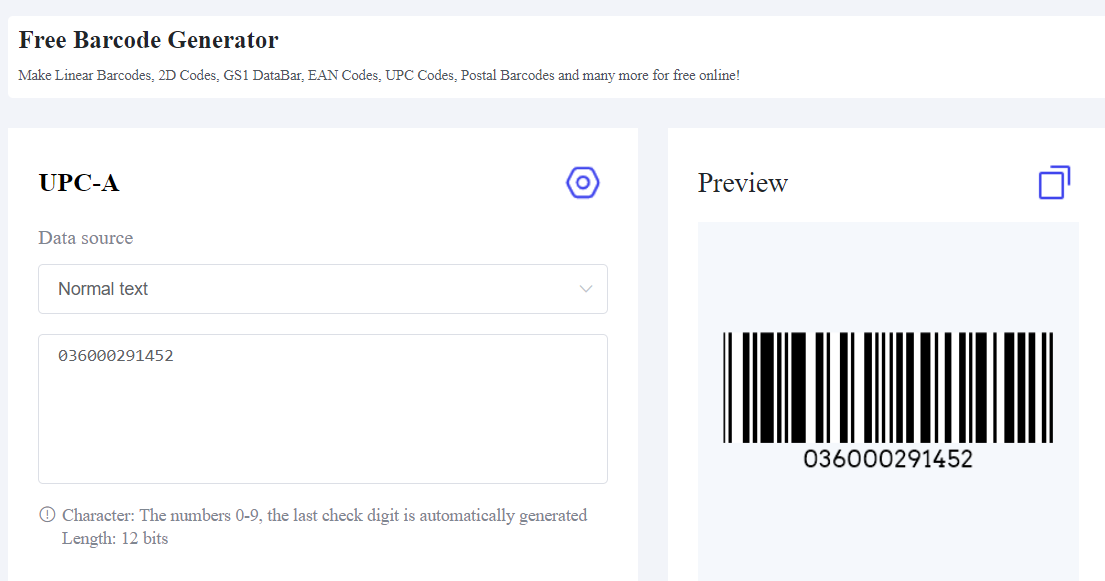

Step 1: Access the Tool

To get started, visit the backroom barcode generator.

Step 2: Select Barcode Type

Next, choose the type of barcode that suits your needs.

Step 3: Input Data and Create

Enter the relevant data that you want the barcode to represent. This data could include:

Product Numbers: Unique identifiers for each product.

SKU (Stock Keeping Units): Specific codes used to track inventory.

Storage Location Codes: Identifiers for specific locations within the backroom or warehouse.

Make sure the data is accurate and matches your inventory management system.

Step 4: Customize Barcode Settings

Many barcode generators allow you to customize settings such as:

Barcode Size: Adjust the size of the barcode to fit your labels.

Text Display: Decide whether you want the numeric code displayed beneath the barcode.

Color Options: Some systems allow you to change the color of the barcode for better visibility.

Step 5: Download and Print

Once your barcode is generated, you can download it in a suitable format.

Download: Save the barcode file to your computer.

Print: Use a barcode label printer or a standard printer with adhesive label sheets to print your barcodes. Ensure that the print quality is high enough for barcode scanners to read without issues.

Step 6: Apply Barcodes

Finally, attach the printed barcodes to your products, shelves, or storage bins. Make sure the barcodes are easily accessible and visible for scanning.

By following these steps, you can efficiently generate and implement barcodes for your backroom, significantly improving your inventory management processes.

Application of the Barcode Generator

A backroom barcode generator has numerous applications across various sectors. Here are some of the most common uses:

1. Inventory Management

The primary application of a backroom barcode generator is inventory management.

By labeling each item and storage location with barcodes, you can efficiently track inventory levels, movements, and locations.

This reduces the chances of stockouts or overstock situations and ensures accurate inventory records.

2. Order Fulfillment

In warehouses, barcodes generated using a target backroom barcode generator are crucial for order fulfillment.

Each item in an order can be scanned to verify its inclusion, reducing errors and improving order accuracy. This leads to faster and more reliable shipping processes.

3. Stocktaking

Regular stocktaking is necessary to maintain inventory accuracy. With barcodes, the process becomes quicker and more precise.

Scanning each item or shelf location with a barcode scanner provides data updates, eliminating the need for manual counting and reducing human errors.

4. Product Identification

Barcodes serve as unique identifiers for products, making it easy to locate items quickly.

In a large warehouse or backroom, this can significantly speed up the process of finding and retrieving products, improving overall efficiency.

All in all, a backroom barcode generator is an indispensable tool for any business looking to improve its inventory management processes.

By simplifying the creation of barcodes, it helps in reducing errors, saving time, and ensuring accurate tracking of products. Whether you are in retail, healthcare, manufacturing, or any other industry, implementing a barcode system can significantly enhance your operational efficiency.

By integrating a backroom barcode generator into your business operations, you can achieve a higher level of organization and accuracy, ultimately leading to better service delivery and customer satisfaction.