For businesses dealing with bottled products, the barcode on bottles ensures accurate tracking from production to sale, whether the product is a beverage, pharmaceutical, or any other bottled item.

This guide covers the types of barcodes used on bottles, how to generate and apply them, and best practices for ensuring they are readable and compliant with industry standards.

Types of Barcode on Bottles

UPC-A: Commonly used in the USA and Canada, UPC-A barcodes are 12 digits long. They are widely recognized and used for retail products.

EAN-13: This barcode is used globally, including in Europe. It is 13 digits long and is the international standard for barcodes on retail products.

ITF-14 and SCC-14: These barcodes are used for shipping and outer cases. They are crucial for logistics and distribution, ensuring that cases and pallets are correctly tracked.

How to Choose the Right Barcode on Bottles?

Retail Products: For items sold individually, EAN-13 or UPC-A are the most appropriate choices. They are designed for retail environments and are easily scannable at the point of sale.

Logistics and Distribution: For cases and pallets, ITF-14 or GS1-128 barcodes are more suitable. These barcodes are designed to be read in warehouse and logistics environments, facilitating the tracking of larger shipments.

How to Generate Barcode on Your Bottles?

1. Select the Barcode Type

Determining the appropriate barcode type is essential. The choice depends on your product and market requirements. For example, if you are selling products internationally, EAN-13 might be preferable to UPC-A.

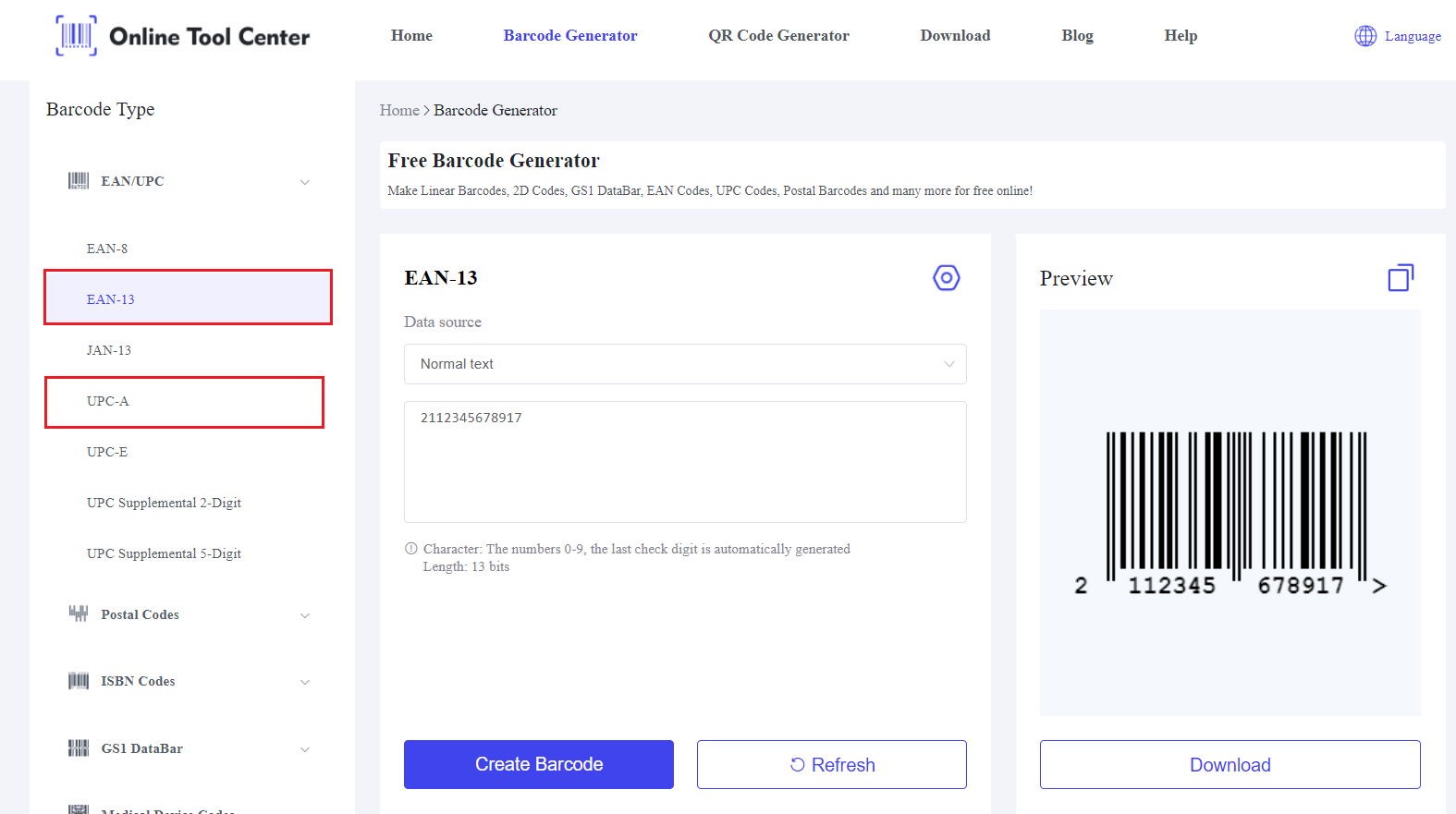

2. Generate the Barcode

You can generate barcodes using a free online barcode generator. Ensure that the barcode you generate is globally unique and compliant with industry standards.

3. Format and Size the Barcode

Following guidelines for barcode dimensions and the placement of human-readable text is crucial. Barcodes must be formatted correctly to be scannable and compliant with industry standards.

4. Print the Barcode

Using barcode printers is essential to ensure that barcodes are readable. Avoid truncation and maintain the proper width-to-height ratio.

Quality printing prevents issues such as blurring and smudging, which can hinder barcode scanning.

Best Practices for Applying Barcodes to Bottles

Placement

Position barcodes in a location where they are easily scannable. Ensure a clear “Quiet Zone” around the barcode, a blank space that helps scanners read the barcode without interference.

Material and Environment Considerations

Choose label materials that can withstand the bottle’s environment.

For instance, if the bottles will be refrigerated or exposed to moisture, the labels must be durable under those conditions.

Testing barcodes under different environmental conditions ensures their durability and readability over time.

FAQs

1. What is the barcode on a liquor bottle?

The barcode on a liquor bottle is typically an EAN-13 or UPC-A barcode. These barcodes are essential for retail products, enabling efficient tracking, inventory management, and sales transactions.

The EAN-13 barcode, used globally, contains 13 digits, while the UPC-A barcode, common in the USA and Canada, has 12 digits.

2. Do different sizes of bottles require different barcodes?

Yes, each size and variation needs a unique barcode to track inventory accurately.

All in all, a proper barcode on bottles is essential for effective inventory management and sales tracking.

By following the guidelines and best practices outlined in this guide, you can ensure compliance and operational efficiency.

Utilize a free online barcode generator and stay updated with industry standards to maintain accuracy and efficiency in your operations.