Tracking the movement of every item in a warehouse can be challenging, but warehouse barcodes provide a reliable solution. Barcodes allow warehouse managers to accurately locate items, record inbound and outbound movements, and conduct efficient inventory counts. By organizing complex processes, barcodes bring structure to warehouse management.

Barcode technology not only enhances efficiency but also significantly reduces manual errors. Today, creating barcodes is accessible and economical; online barcode generators allow anyone to generate professional barcodes with just a few clicks. This ease of use makes transforming a chaotic warehouse into a streamlined operation achievable and cost-effective.

Let's explore how warehouse management barcodes can optimize various operational stages and how to easily create warehouse-ready barcodes with an online barcode generator.

The Role of Warehouse Barcodes in Inventory Management

1. Boosting Inventory Management Efficiency: Barcodes streamline every stage of inventory operations. Assigning a unique barcode to each item allows warehouse staff to quickly retrieve item details with a barcode scanner. This digital approach offers real-time inventory updates, cutting down on the time and errors associated with manual record-keeping.

2. Increasing Accuracy in Inbound and Outbound Management: Traditional inbound and outbound workflows often rely on manual checks, which can lead to errors and omissions. With warehouse barcodes, staff can simply scan each item's barcode, automatically recording each movement in the system. This automated process ensures data accuracy and speeds up warehouse operations.

3. Simplifying Inventory Counts: Barcode technology has transformed inventory counts, making them faster and more accurate. Instead of manually tallying each item, staff can scan barcodes to instantly update inventory records. This reduces repetitive tasks and boosts productivity across the warehouse.

4. Enhancing Traceability: Barcodes give each item a unique identifier, enabling end-to-end traceability from receiving through storage and dispatch. This real-time visibility allows managers to track the status and movement of goods, supporting transparency in warehouse operations. This capability is especially useful for high-security goods such as pharmaceuticals and electronics.

Key Applications of Barcodes in Warehouse Management

● Receiving Management: When items are received, attaching a warehouse barcode and scanning it into the system allows for immediate inventory updates and accurate tracking of stock levels.

● Location Management: In large warehouses, location management is essential. By attaching barcode labels to shelves or storage areas, scanning barcodes of items and locations ensures precise stock placement, avoids confusion, and maximizes space utilization.

● Transfer Management: When items are transferred between warehouses, warehouse barcodes streamline the process. Barcode scanning accurately records item movements, reducing error rates and improving the efficiency of internal transfers.

How to Generate Warehouse Barcodes for Free

Using barcodes for inventory control and tracking is essential in warehousing. With free online barcode generators, managers can easily create barcodes tailored to their warehouse needs.

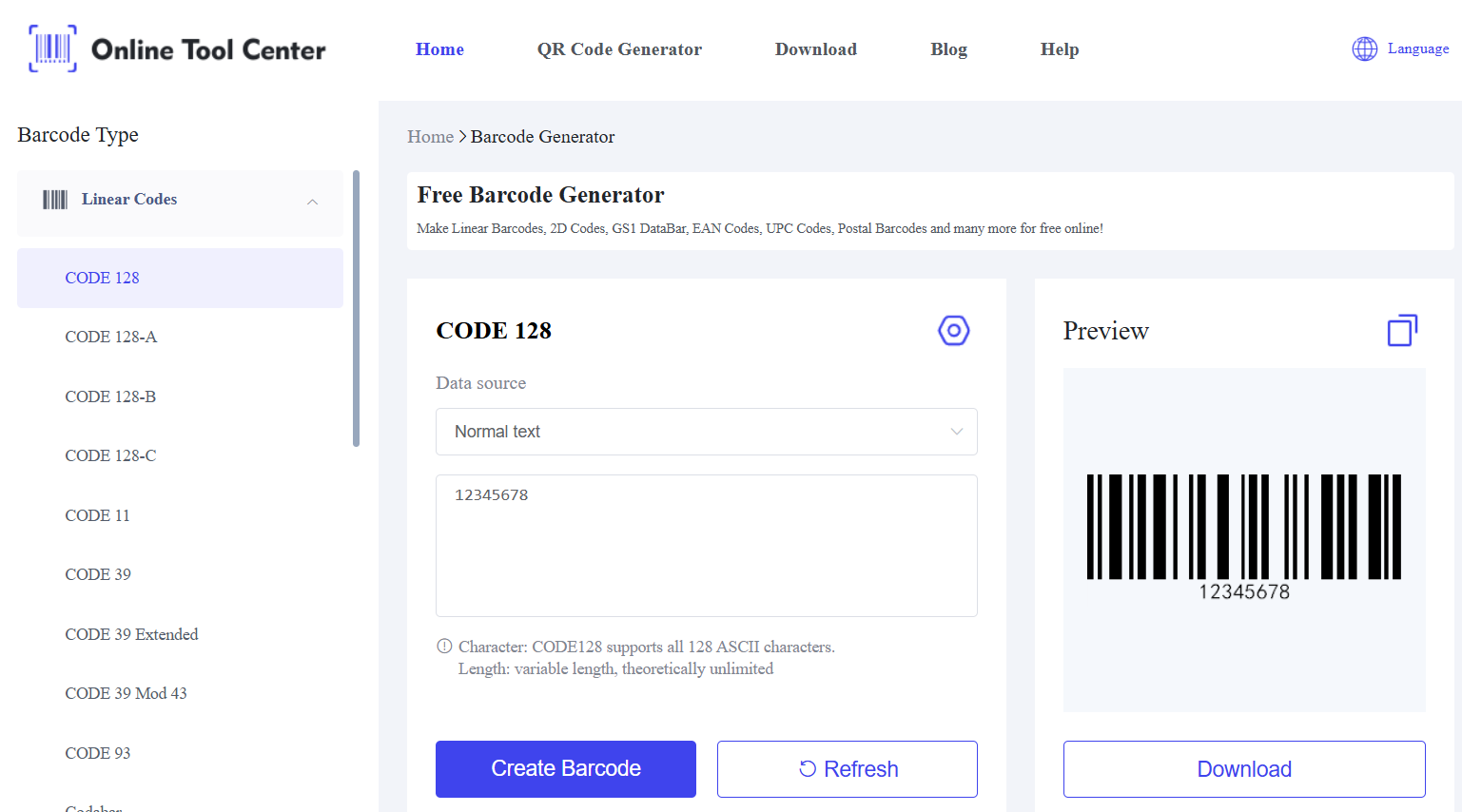

1. Select a Barcode Type: Choose a barcode type suited to your warehouse's needs. Code 128 is often ideal for warehouses due to its high capacity and support for both letters and numbers, making it excellent for unique item identification. Other formats, like EAN-13, are also available if required.

2. Enter Item Information: Use the Code 128 barcode generator to input item details, such as serial numbers or batch numbers, to create a unique barcode for each item.

3. Customize the Barcode Style: Most online barcode generators allow adjustments to barcode dimensions, resolution, and background color to fit your labeling needs. For barcodes stored long-term or in challenging environments, setting an appropriate resolution improves durability and scan accuracy.

4. Download the Barcode: After verifying the settings, click “Download” to generate your barcode image. Many generators offer formats like PNG and JPG, making it easy to print and apply.

5. Print and Attach: Import the barcode image into your printing software or print directly to produce high-quality labels. Affix the barcode to each item in an accessible location to avoid misreads or missed scans.

Using a free online barcode generator allows warehouse managers to create high-quality barcodes without expensive software or specialized equipment. The versatility of online generators enables cost-effective, adaptable solutions for inventory control.