Barcode stickers have become essential in industries ranging from retail and healthcare to logistics and manufacturing. Their role in streamlining inventory management, product labeling, and pricing makes them indispensable for businesses of all sizes.

In this guide, we will discuss barcode stickers, the materials used, the types of printers required, and the best practices for creating high-quality barcode labels. We'll also address how to generate barcodes using a barcode generator and cover essential technical considerations.

What Are Barcode Stickers?

Barcode stickers are adhesive labels featuring barcodes that store encoded data. These barcodes are machine-readable for product tracking, inventory management, and pricing.

Barcode labels come in various sizes and materials depending on their application, whether they are being used in a warehouse, retail store, or healthcare facility.

By providing accurate, machine-scannable data, barcode stickers help businesses save time, reduce human error, and increase operational efficiency.

Types of Materials Used for Barcode Stickers

Choosing the right material for your barcode stickers is crucial, as it impacts durability and readability. Several types of materials are available, each suited to different environments:

1. Paper:

Paper labels are cost-effective and ideal for indoor environments, such as retail and office use. However, they may not hold up well in environments exposed to moisture, chemicals, or extreme temperatures. These are typically used for short-term applications, such as barcode price stickers in retail.

2. Polypropylene:

A more durable option than paper, polypropylene barcode stickers are resistant to water, chemicals, and moderate handling. They are commonly used in industries where durability is required but not under extreme conditions. For instance, refrigerated goods often use polypropylene labels.

3. Polyester (PET):

Polyester is a high-durability option, resistant to harsh environments such as industrial settings or outdoor applications. Polyester barcode stickers can withstand high temperatures, chemical exposure, and extensive handling, making them ideal for long-lasting applications.

4. Vinyl:

Vinyl barcode stickers are flexible and durable, often used in outdoor environments where weather resistance is key. These labels can endure exposure to UV rays, moisture, and abrasion. For businesses that require long-lasting, tough labels, vinyl is an excellent option.

By selecting the right material, you ensure that the barcode stickers are scannable and durable throughout the product's lifecycle.

How to Print Barcode Stickers?

Printing barcode stickers accurately requires the right equipment and understanding of the label material and format. Here are the primary methods:

1. Using a Barcode Sticker Printer

A barcode sticker printer is essential for businesses needing large volumes of barcode labels or customized prints. There are two main types of printers commonly used:

These printers use heat to transfer ink from a ribbon onto the label material. Thermal transfer is ideal for durable materials like polyester or vinyl, and it produces long-lasting, crisp barcodes. These printers are often used in industrial environments where durability is key.

● Direct Thermal Printers:

Direct thermal printers use heat-sensitive labels and do not require ink or toner. These printers are cost-effective for short-term use, such as shipping labels or barcode price stickers.

Looking for a thermal label printer that can do it all? Check out the HPRT SL32. This little guy can print labels for everything from food to shipping, and it's super easy to use on your computer or phone. Plus, it comes with free software to help you design the perfect labels.

However, direct thermal labels are not as durable, as they can fade over time, especially when exposed to sunlight or heat.

2. Outsourcing to Professional Printing Services

For businesses that need high-quality barcode labels but do not have a barcode sticker printer, outsourcing the task to a professional service is a viable option. These services can produce labels in large quantities and offer a variety of materials and finishes to meet your needs.

No matter which printing option you choose, testing the scannability and durability of your labels before mass production is crucial.

Generating Barcodes for Your Stickers

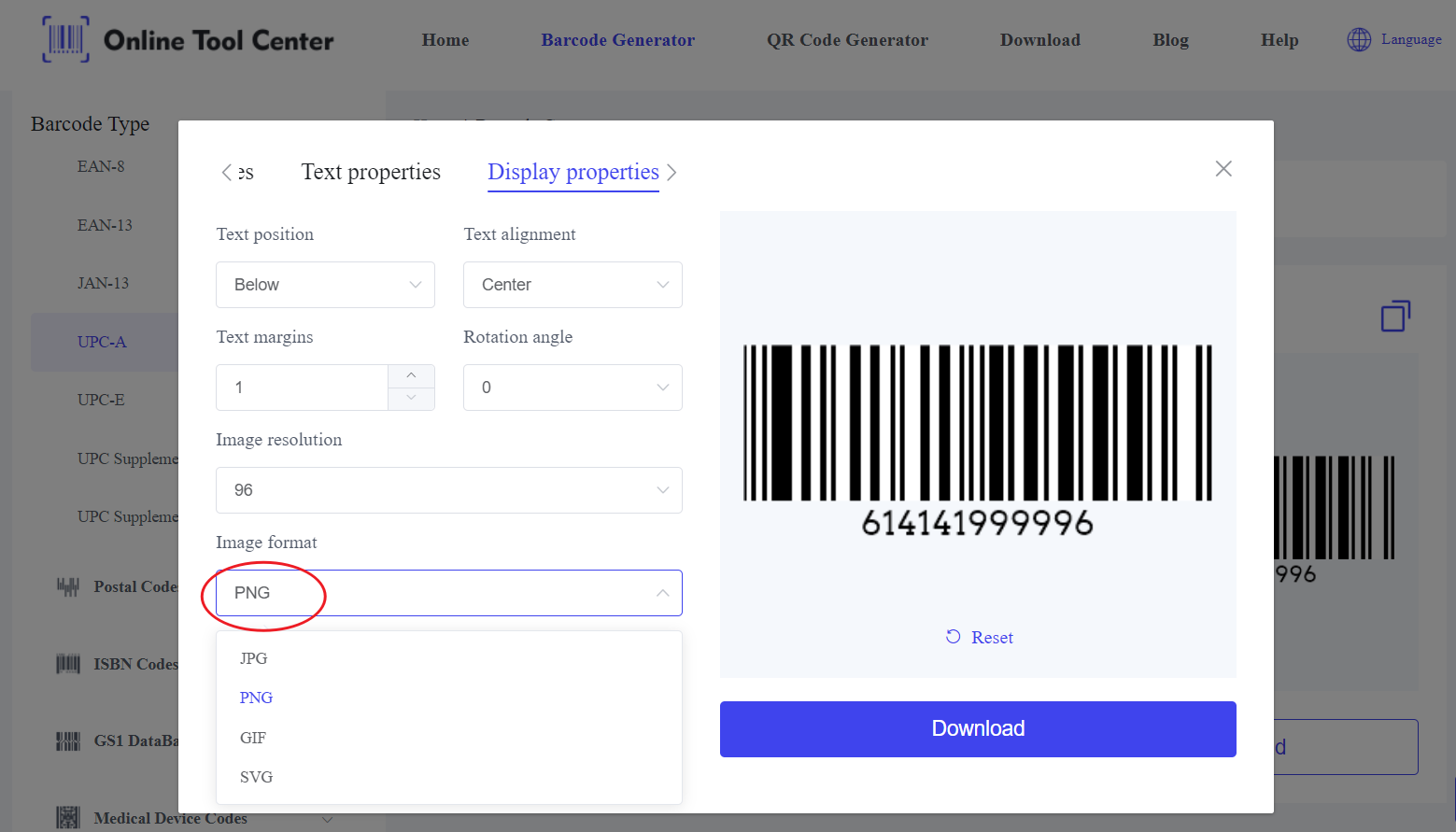

To create the actual barcode that will be printed on the stickers, you need a reliable barcode generator. A barcode generator allows you to create barcodes in various formats such as QR codes, UPC, or Code 128, depending on your specific needs.

One useful feature is the ability to download your barcode in high-resolution formats like barcode sticker PNG. This ensures that the image quality is maintained during printing.

The online barcode generator offers an easy and free way to generate your barcodes for printing.

Best Practices for Applying Barcode Stickers

Once you have your barcode stickers, how you apply them can affect their usability and longevity. Here are some best practices:

● Positioning:

Ensure the barcode is placed in an area of the product where it won't be damaged or distorted. Avoid placing the barcode sticker over curved surfaces that could make scanning difficult by barcode scanners.

● Testing:

Always test a sample of your barcode stickers before full-scale production. Make sure the barcode is readable from multiple angles and under different lighting conditions.

● Environment Considerations:

For items that will be exposed to harsh conditions, such as outdoor equipment or industrial products, select durable materials like polyester or vinyl and ensure the barcode remains scannable even after prolonged exposure to environmental elements.

To sum up, selecting the right materials and printing methods for your barcode stickers ensures they meet the needs of your business. Whether you are labeling products for retail or tracking assets in a warehouse, barcode stickers simplify these tasks and improve accuracy.

Using a free barcode generator allows you to design barcodes suited to your specific needs. Paired with the right barcode sticker printer, you can easily create high-quality barcode stickers that stand the test of time.

From paper labels for short-term retail applications to durable vinyl stickers for outdoor use, understanding the nuances of barcode stickers helps you make informed decisions for your business.