Among the many types of barcodes, the thin barcode offers a solution for products with limited space for labeling. This article will explain what makes a barcode "thin," how thin a barcode can be without affecting scan reliability, and how to generate thin barcodes for different uses.

What is a Thin Barcode?

A thin barcode refers to a barcode where the black bars and white spaces are narrower than the standard size, allowing it to fit in small areas.

Thin barcodes are typically used in packaging where space is limited, but they still need to be readable by standard barcode scanners. While most 1D and 2D barcodes can be scaled down to reduce their footprint, this is not without limitations.

Thin barcodes are particularly useful for industries like healthcare, electronics, and cosmetics, where labels need to contain a lot of information but have limited space on the product.

These smaller barcodes can be a challenge to print and scan, but with the right technology, they can be just as effective as larger, more traditional barcodes.

How Thin Can a Barcode Be?

One of the most important questions is, "How thin can a barcode be before it stops being scannable?" This depends on several key factors:

1. X-Dimension: The X-dimension refers to the width of the narrowest bar or space in a barcode. The standard X-dimension varies based on the barcode type, but for most linear barcodes (like UPC and Code 128), the X-dimension can range from 0.2 mm to 0.33 mm. The thinner the X-dimension, the smaller the barcode can be, but making it too thin can make it difficult for scanners to read.

2. Barcode Type: Different barcode types have different limits for how thin they can be.

● For 1D barcodes (like UPC and Code 128), the X-dimension can go as small as 0.2 mm (200 microns), though most applications stick to 0.26 mm or larger to ensure reliable scanning.

Code 128 is one of the most compact 1D barcodes. It is commonly used for shipping and inventory labels. It can be scaled down significantly without sacrificing readability.

UPC barcodes, used in retail, can shrink to about 80% of their original size, with the smallest bars being 0.264 mm wide.

● For 2D barcodes like DataMatrix or QR codes, the smallest modules (squares) can measure 0.254 mm or less, making them ideal for small products like medical devices or microchips.

DataMatrix codes are used extensively in healthcare and electronics because they store more data in a compact space, often making them the thinnest overall when reduced.

The thinnest barcodes can have bar widths or module sizes as small as 0.2 mm for 1D and 0.254 mm for 2D, but practicality often depends on the printing and scanning equipment used.

3. Scanner Resolution: Barcode scanners have limitations based on the resolution they can read. High-resolution scanners are better suited to reading thin barcodes. Low-resolution or older scanners may struggle with very narrow bars, which can lead to scanning errors.

4. Quiet Zone: This is the blank space around the barcode that helps scanners identify where the barcode starts and ends. Even when a barcode is thin, the quiet zone must remain adequately sized to ensure reliable scanning. Typically, the quiet zone needs to be about 10 times the width of the narrowest bar in the barcode.

The Challenges of Thin Barcodes

While thin barcodes offer space-saving benefits, they also present several challenges:

● Printing Quality: High-quality printing is vital for thin barcodes. If the print is poor, lines can blur, causing failed scans. Using a barcode printer ensures clear, accurate barcodes for scanning.

● Scanning Distance: Scanners have an optimal distance for reading barcodes. Thin barcodes typically require the scanner to be closer than with a regular-sized barcode. If the scanner is too far away, it may fail to recognize the thin lines accurately.

● Environmental Factors: Barcodes can become damaged due to exposure to moisture, dirt, or wear and tear. Thin barcodes, with their smaller size and thinner lines, are more susceptible to damage than larger barcodes.

Practical Uses for Thin Barcodes

Thin barcodes are increasingly used in industries where space is limited but accurate tracking and scanning are essential. Here are some practical examples of how thin barcodes are utilized:

1. Healthcare and Pharmaceuticals

In hospitals and pharmacies, medication vials, syringes, and test tubes often have very limited space for labeling.

Thin barcodes (often Code 128 or DataMatrix) are used to track these items, ensuring patient safety and inventory accuracy.

For example, a vial of insulin or a single-use syringe may have a small label that includes a thin barcode for scanning at every stage—from pharmacy inventory to patient administration.

2. Small Electronics

The electronics industry often deals with tiny components like circuit boards, semiconductors, and memory chips, which need to be tracked during manufacturing.

A thin barcode, like a reduced-size Code 39 or QR code, is applied to these components to manage them through the production process.

For instance, microchips for mobile phones or laptops have thin barcodes etched or printed directly onto the part, allowing easy scanning despite the small surface area.

3. Cosmetics and Personal Care Products

Many beauty and personal care products come in small containers with limited label space, such as lipstick tubes, small makeup palettes, or perfume samples.

These products often use thin UPC barcodes to ensure they can be tracked in inventory, scanned at retail points, and identified for quality control.

A small tube of mascara, for example, may have a thin barcode on the bottom to save space for branding and product details on the rest of the packaging.

4. Jewelry and Accessories

Jewelry items, such as rings or watches, have minimal space for product labels. Thin barcodes are often used on price tags or packaging to maintain inventory and assist in retail sales.

A thin Code 128 barcode on a tiny tag attached to a necklace can ensure it is properly identified during sales or stock management, without the need for a large, obtrusive label.

How to Generate Thin Barcodes?

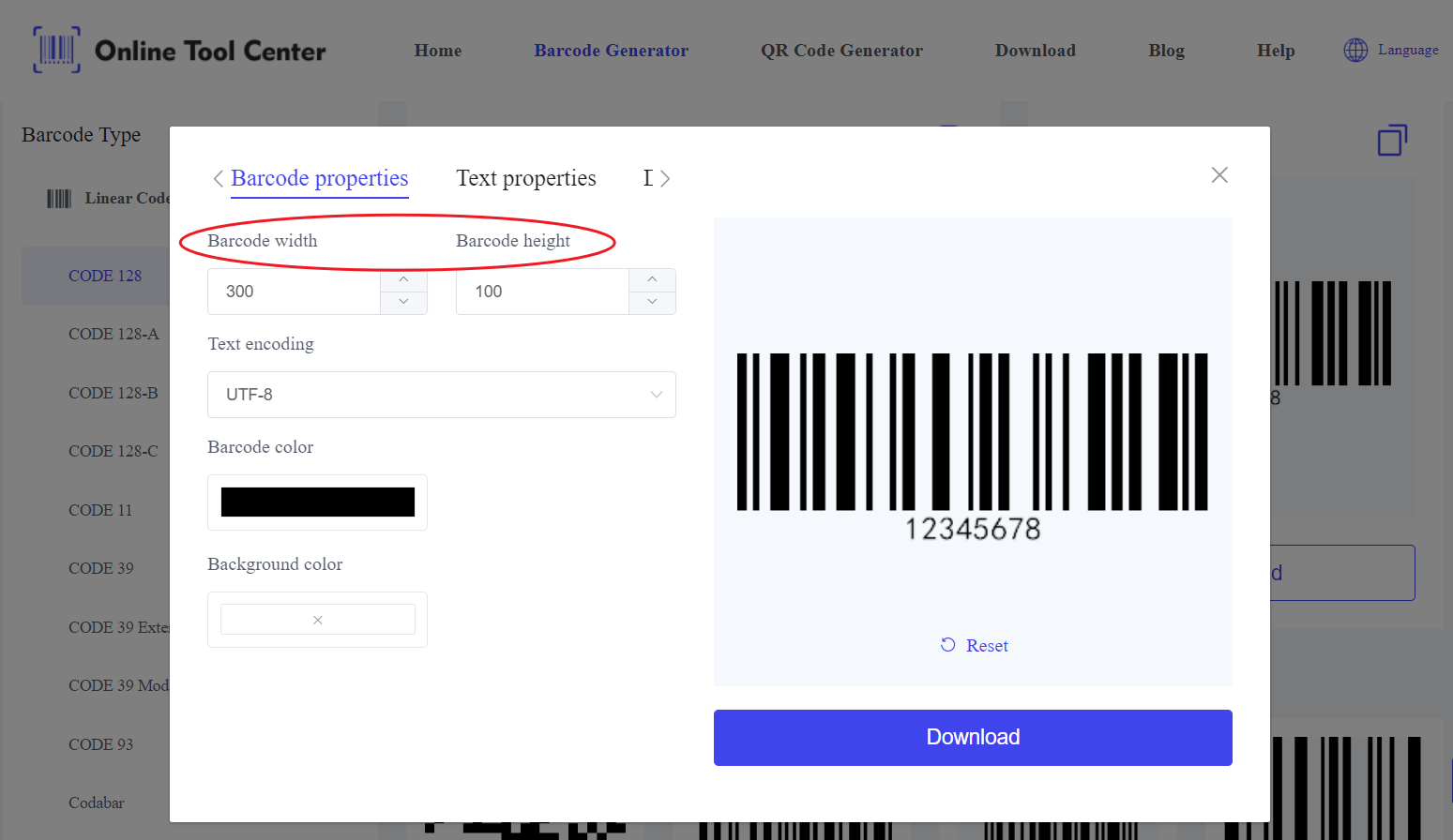

Generating a thin barcode can be done easily using a barcode generator. The barcode creator let users customize the width and dimensions of the barcode to fit their specific needs.

When creating a barcode, be sure to adjust the X-dimension to the appropriate level for your application, ensuring that it remains scannable with the equipment you use.

You can select from different barcode types, including Code 128, QR codes, and UPC, and modify them to fit your space requirements. By using a high-resolution printer and testing the barcode with your scanner, you can ensure that your thin barcode remains fully functional.

All in all, a thin barcode offers a compact, space-saving solution for industries requiring high-density information on limited label space.

However, designing and implementing a thin barcode requires careful consideration of printing quality, scanner capabilities, and environmental conditions.

By understanding how thin a barcode can be and using the right tools like a barcode generator, you can take full advantage of this flexible labeling solution.

To create your thin barcodes, visit our website and easily generate barcodes tailored to your specific needs. This will ensure you have reliable and space-efficient barcodes ready for use in any setting.