Rugged barcodes have become indispensable in areas that require reliability and longevity. These robust barcodes are engineered to withstand extreme conditions, ensuring uninterrupted data capture and management in environments where standard barcodes would fail.

What Are Rugged Barcodes?

Rugged barcodes are designed to endure harsh environments such as extreme temperatures, moisture, dust, and physical abrasion.

These barcodes are often thermal transfer printed on materials like polyester or polypropylene, which offer superior durability compared to paper labels. Alternatively, laser etching on metal surfaces creates extremely durable and permanent barcodes.

Importance of Rugged Barcodes

1. Reliability in Harsh Conditions:

Rugged barcodes are crucial in industries like manufacturing, logistics, and construction, where environmental conditions can quickly degrade standard barcodes. They ensure that essential information remains accessible, reducing the risk of operational delays and errors.

2. Enhanced Data Accuracy:

By maintaining readability under challenging conditions, rugged barcodes improve data accuracy. This is vital for inventory management, asset tracking, and quality control processes.

How to Make Rugged Barcodes?

Creating rugged barcodes that withstand harsh environments involves careful selection of materials, printing methods, and protective measures. Below is a comprehensive guide on how to make rugged barcodes.

Step 1: Understand the Requirements

Before creating rugged barcodes, it's essential to understand the specific conditions they will face:

● Environmental Conditions: Consider factors like temperature extremes, moisture, dust, and UV exposure.

● Physical Stress: Evaluate potential for abrasion, impact, and chemical exposure.

● Duration of Use: Determine how long the barcodes need to remain readable.

Step 2: Select the Appropriate Coding and Printing Method

Utilize a free online barcode generator to create your barcodes efficiently. This tool supports various barcode types and ensures accurate, high-quality results suitable for different printing methods.

The printing method significantly impacts the durability of barcodes. Here are some robust options:

● Thermal Transfer Printing: Uses heat to transfer ink from a ribbon to the label material. It produces high-quality, durable prints that resist smudging and fading.

The most common durable materials for thermal transfer printers include:

● Polyester (PET): Offers excellent resistance to moisture, chemicals, and abrasion.

● Polypropylene (PP): Known for its durability and resistance to solvents and acids.

● Polycarbonate: Extremely tough and resistant to impacts, often used for high-stress applications.

● Laser Etching: Involves using a laser to engrave the barcode onto the material. This method is highly durable and ideal for metal surfaces or high-temperature environments.

● Dot Peen Marking: Creates barcodes by indenting the material with a series of dots. It's suitable for direct part marking on metals and other hard surfaces.

Step 4: Apply Protective Coatings

Protective coatings can enhance the durability of barcodes by providing an extra layer of defense against environmental factors:

● Laminate Coating: A clear, protective film that shields barcodes from abrasion, moisture, and chemicals.

● UV-Resistant Coating: Protects barcodes from UV light degradation, which is essential for outdoor applications.

● Chemical-Resistant Coating: Guards against exposure to harsh chemicals and solvents.

Step 5: Test for Durability

Before full-scale implementation, test the rugged barcodes to ensure they meet the necessary durability standards:

● Environmental Testing: Expose the barcodes to extreme temperatures, moisture, and UV light to check for any deterioration.

● Physical Testing: Subject the barcodes to abrasion, impact, and chemical exposure to assess their resilience.

● Scanning Reliability: Ensure that the barcodes remain readable with standard and industrial barcode scanners under all conditions.

Step 6: Implement and Monitor

Once the rugged barcodes are tested and verified, implement them in your operations:

● Application: Use the appropriate adhesive for the barcode labels to ensure they stay affixed to surfaces in challenging conditions.

● Monitoring: Regularly inspect the barcodes for wear and tear, and replace them as needed to maintain data accuracy.

Applications of Rugged Barcodes

1. Manufacturing:

In an industrial manufacturing setting, rugged barcodes are used to track parts and products throughout the production process.

2. Logistics and Warehousing:

Rugged barcodes facilitate efficient inventory tracking and management in warehouses. They are resistant to the dust and physical handling typical in these settings, ensuring reliable data capture.

3. Construction:

On construction sites, rugged barcodes are used to track tools, equipment, and materials. They can withstand exposure to dirt, mud, and rough handling, providing reliable asset management.

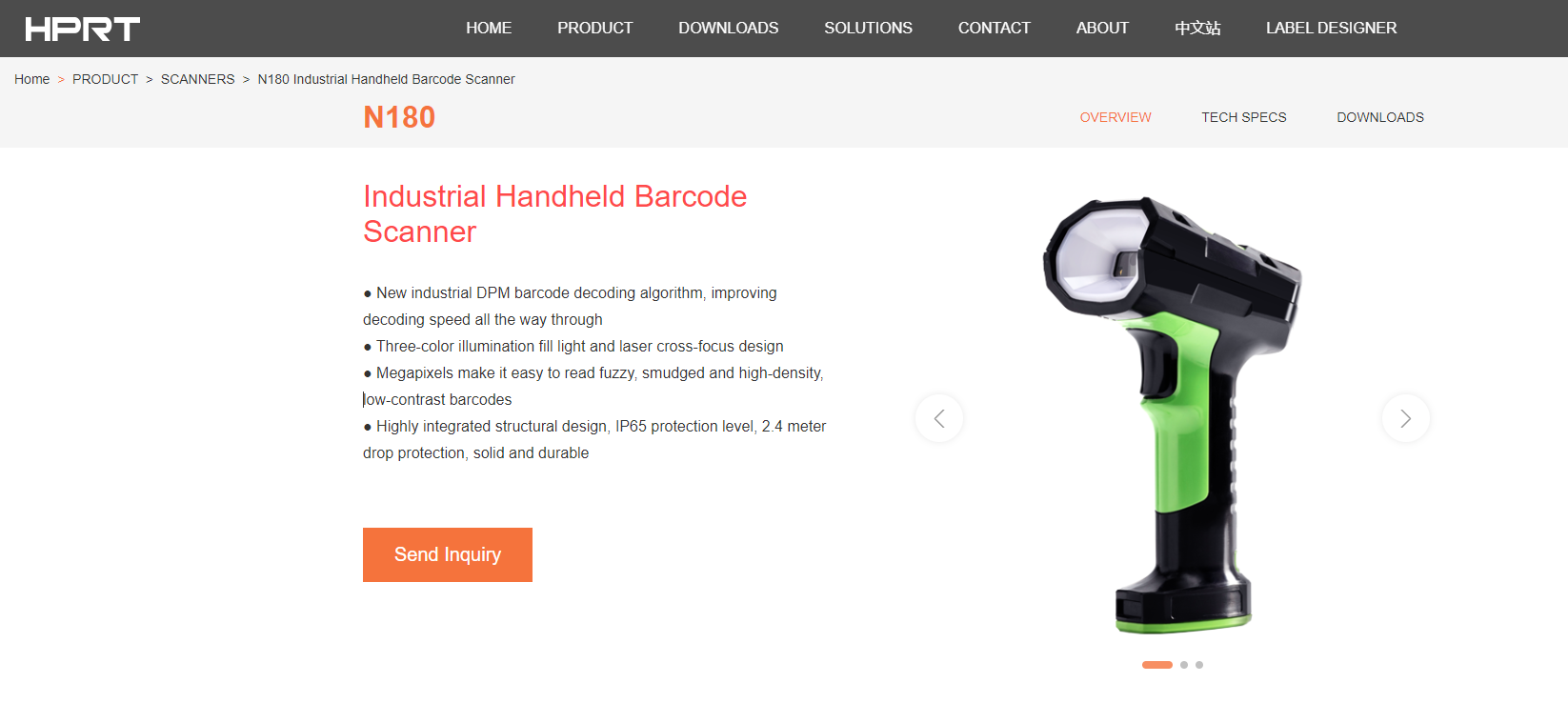

Choosing the Right Rugged Barcode Scanner

To effectively read rugged barcodes, using a rugged barcode scanner is essential. These scanners are built to perform in demanding conditions, featuring durable construction and advanced scanning technology.

They can read barcodes that are dirty, damaged, or poorly printed, ensuring continuous operation and data integrity.

Key Features of Rugged Barcode Scanners:

● Durability: Built to withstand drops, vibrations, and exposure to dust and water.

● Scanning Capability: Ability to read various barcode symbologies, even in poor conditions.

● Ergonomics: Designed for comfortable use over extended periods.

Rugged Tablet PCs with Barcode Generators

For mobile operations, rugged tablet PCs equipped with barcode generators are invaluable. A rugged tablet PC barcode generator allows workers to generate, scan, and manage barcodes directly from the field.

These devices combine the portability of a tablet with the durability needed for industrial use, enhancing workflow efficiency.

Final thoughts, rugged barcodes are essential for industries operating in challenging environments. They offer a reliable solution for data capture and asset management, ensuring accuracy and efficiency.

With tools like rugged barcode generators, scanners, and rugged tablet PC barcode generators, you can create and manage durable barcodes tailored to your needs.

Explore the robust barcode generation solutions available to enhance your operational efficiency and reliability.

By incorporating rugged barcodes into your operations, you can ensure that critical data remains accessible, even in the harshest conditions.